Inspections are a crucial part of the operations of many industrial sectors. Conducting regular, thorough examinations helps to ensure reliable equipment performance, worker safety and more in the manufacturing, energy, transportation and other industries.

As with so many other aspects of industrial activities, robotics is playing an increasingly central role in conducting inspections. Today, robots can inspect manufacturing equipment, pipelines, buildings, transportation systems and much more. Automation capabilities are improving, and the costs of these technologies are falling, enabling more companies to take advantage of the benefits they provide.

Many of these automated inspection systems use artificial intelligence, or AI, technology. In an approach called deep learning, for instance, you can train a neural network by inputting a large volume of examples of what a standard piece of equipment looks like and what a damaged one looks like. The system can use this information to identify damage during real-world use. Robots can also use artificial intelligence technology to learn to navigate industrial facilities and avoid obstacles.

Automated inspection devices allow workers to conduct inspections remotely. Sometimes, the bots can even perform them entirely autonomously. In both cases, using these tools provides significant potential advantages for industrial companies.

Types of Robotic Inspection Technologies

Inspection robots exist for various use cases across multiple industries. Depending on their purpose, they use different technologies. Some of these bots are commercially available, but companies that need to perform inspections sometimes also develop bots for their own use, which they do not sell commercially. The devices in this second category might be more specialized, but many commercially available robots are highly customizable as well.

The following are some of the common types of robotic inspection technologies in use today.

- Remote Inspection Robot

Modern robotics enables reviewers to conduct inspections entirely remotely. They can deploy remote monitoring robotic systems into various types of locations to perform varied kinds of checks. These bots can operate with varying degrees of autonomy. Workers may control them remotely, or the devices may operate mostly automatically while the human worker reviews the collected data from a separate location.

- Robotic Manipulation Systems

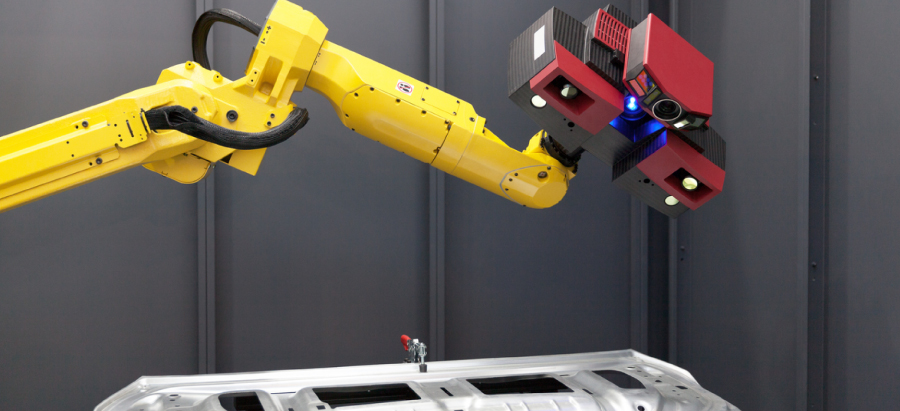

Another type of inspection robot, called a robotic manipulation system, stays in one place but offers advanced functionality. These devices typically have multiple joints and can move flexibly to fit into tight spaces and perform complex tasks. You can attach a variety of tools to these types of systems. They might also work in tandem with remote inspection devices to move them closer to where they need to go. A remote inspection robot might also transport a manipulation system to a new location where it can perform a task more intricate than the remote inspection bot could.

- Magnetic Wheeled Robot

Some remote inspection robots use magnetic wheels to traverse metal industrial equipment. Workers can deploy these bots to enable remote inspections of machinery, pipelines and other assets. These devices can often climb up vertical surfaces and even make their way over irregularly shaped objects. You can affix a wide range of inspection equipment to these bots.

- Remote Visual Inspection Robot

Thanks to inspection robots, visual inspections of industrial equipment are frequently performed remotely. Mounting a camera to capture still or video footage enables companies to monitor and inspect equipment and then review the footage at any later time. These tools are often outfitted with lighting systems as well. Visual inspection may be the most common type of remote examination performed today.

- Scanning System Robot

Other inspection bots use one of several scanning technologies to conduct inspections. These devices can often carry a range of scanner types and be configured to perform various types of examinations. Scanner types include those for ultrasonic, phased array, eddy current, time of flight diffraction, radiographic and magnetic particle testing. You can affix these scanners to many different types of robots, including remote inspection and robotic manipulation systems.

- Drones

Another, perhaps more familiar, high-tech tool used to perform inspections is the drone. Also known as unmanned aerial vehicles, or UAVs, you can attach a variety of sensors to drones and send them to conduct examinations from the air. This capability is especially useful for checks of equipment located at substantial heights or spread out across a wide area. Drones can vary in size, so they may also be able to fit into small spaces.

How Are Industrial Sectors Using Robotic Inspections?

As suggested by the types of robots that are available, automated inspection systems can perform a range of tests for various industries. These robotic monitoring systems can examine machinery, buildings, products and even natural environments. Some of the industries that use inspection robots include manufacturing, energy and transportation.

- Manufacturing

Performing regular inspections on machinery used for manufacturing is crucial to keeping plants up and running. Automated tools can accomplish, or assist in performing, many of the checks conducted in industrial facilities. Robots with magnetic rollers can climb up the sides of manufacturing equipment to perform inspections and can do checks inside the machinery as well. These bots can inspect the insides of bores and pipes as well as analyze weld integrity from the outside. They can also examine turbine blades for cracks and conduct visual inspections of tanks, vessels, pipes, cooling towers and other equipment components. Additionally, manufacturing companies can use robots to inspect the buildings in which they operate. Robots can often access roofs, attics, crawlspaces, ducts and other parts of a facility more efficiently and safely than human workers can.

Another use case for inspection robots in the manufacturing sector is that of quality control inspections. Checking the quality of products before sending them to customers is critical to protecting a company’s reputation, but doing so by hand can be time-consuming. Growing numbers of manufacturers are replacing manual inspections with automated ones. Automated quality control tools can use machine vision and laser measurement sensors to conduct inspections either autonomously or semi-autonomously. These systems can inspect the dimension, assembly and other aspects of parts.

- Energy

Accurate inspections of energy generation and distribution equipment is crucial for reliably and safely getting electricity to customers. The energy industry is another industrial sector that frequently uses robotics to conduct inspections.

The oil and natural gas sector is one of the most prominent users of automated inspection equipment. Robotic inspection tools can play a role in everything from getting crude oil out of the ground to getting petroleum products to customers. Oil rig operators use robotics to inspect drilling equipment. It’s especially common to use remotely operated devices for inspecting underwater structures used for offshore oil exploration and drilling.

You can also find robotic inspection tools in oil refineries, which turn crude oil into consumer products. These facilities utilize precise chemical processes and need their equipment to function properly at all times. Manual inspections in these plants can also be dangerous because of the machinery involved.

Power generation facilities may use automated inspection tools as well. Coal-fired boilers, for example, have water walls that require regular visual inspections and wall thickness checks. Devices such as Boiler Wall Cleaning and Inspection (BWCI) bots use magnetic rollers to crawl these walls. As the BWCI moves around the boiler, it automatically conducts these tests and cleans the walls as well.

Utilities also often use automated equipment to inspect the pipelines that transport petroleum products from place to place. Robots can crawl along pipelines performing visual inspections, using ultrasound to check for corrosion and testing for leaks. Utilities can even deploy permanent sensors along pipelines that immediately alert the company if they detect a leak.

As renewables become more prevalent, automated robots are finding more work in the energy sector. Inspectors are using automated technologies, such as drones, to inspect vast fields of solar panels and towering wind turbines.

Drones outfitted with thermal imaging tools can detect anomalies and damage to panels and can survey a field full of panels much faster than a human worker could.

Inspecting wind turbines can be dangerous because of the heights involved. Workers must sometimes hang from cables to perform these examinations. Using drones instead of human workers eliminates these safety hazards.

Drones and other types of robotic devices also inspect power lines and other distribution infrastructure that transports electricity to customers.

- Transportation

Inspection robots also see use in the industrial segments of the transportation sector, including the manufacturing of transportation equipment and the inspections performed to ensure continued safe and reliable operation.

Robots equipped with magnetic rollers can inspect ship hulls, tractor trailers and airplanes for imperfections. Discovering and fixing any defects is crucial for safe operation, so administering regular inspections is vital. However, doing so manually is time-consuming. With automation, these inspections are much more efficient.

NASA is currently experimenting with using robots armed with infrared thermography sensors to inspect aircraft. This sensor technology is needed because of the advanced composite materials being used in the manufacture of modern aviation equipment. Lufthansa Technik, part of German airline Lufthansa, recently filed patents for bots that can both inspect and fix airplane surfaces made of fiber-reinforced composites.

Benefits and Drawbacks of Robotic Inspections

There are numerous reasons that companies may choose to use robots to conduct inspections. Here are a few of them.

- Robots Can Go Places People Can’t

Robots can go many places that people can’t or would rather not go. They can fit into small spaces, easily climb up walls and move around inside machinery or vehicles. This can make inspections more thorough and simpler to perform.

- Using Robots Improves Worker Safety

Using robots allows workers to avoid potentially dangerous inspection sites by enabling them to conduct inspections remotely. Rather than hanging from wires to inspect a wind turbine, for instance, workers can send drones up to examine the blades. Workers can also avoid heavy manufacturing equipment, underwater components of offshore drilling pads and other potentially hazardous locations.

- Robots Increase Efficiency

Robotic inspections can often be completed more quickly than human ones can because they eliminate the need to take equipment apart or otherwise interfere with it to inspect it. Plus, automated inspections can run in the background, while workers attend to other value-added tasks.

- Robots Improve Organization

The data from robotic inspections often gets sent directly to business systems, eliminating the need for a human worker to record data and transfer it from place to place. This data is stored over long periods and is easily accessible at any time. Companies can analyze this data to learn more about the health of their systems and improve their maintenance strategies.

- Robots Lower Costs

Using robots to perform inspections means that industrial companies don’t need to have multiple workers on site for these checks. If they can use fully automated bots, workers don’t need to take extra time out of their workday to conduct inspections. The ease with which these reviews can get finished also means that they can be conducted more frequently, enhancing preventative maintenance activities and reducing the costs associated with performing repairs on equipment.

Drawbacks

Robots are not always the ideal solution, however. Some of their disadvantages are as follows.

- Robots Require a Relatively High Upfront Investment

Although inspections themselves may cost less when using a robot, purchasing robotic inspection equipment does require a substantial upfront investment. Companies may, however, be able to rent these devices or outsource inspections to a company that uses them.

- Robots Don’t Respond Well to All Unexpected Situations

Robots are not quite as versatile as people. While they may exceed at one specific task, they might not be able to adapt if something unexpected occurs. This means that they may not pick up on rare issues that a human inspector might. Because of this limitation, it may be helpful to supplement robotic-powered examinations with occasional human-powered ones.

A More Automated Future?

As robotic tools become more advanced and also more affordable, more industrial companies are using them to perform checks of equipment and facilities. Utilizing these inspection robots can increase efficiency, reduce costs and improve worker safety. As this trend continues, we will see more companies using automated inspection bots and see new kinds of automation tools come about.

It’s crucial that manufacturers and other industrial companies evaluate the use of robotic inspection equipment on a case-by-case basis to ensure that they can get the most out of this advanced technology. They will also need to train workers in how to use these devices and develop a deployment plan so that they can introduce them without disrupting activities. Inspection tools likely won’t be the only robotic or automation equipment a company deploys. Integrating all of these devices, along with the data they produce, into business systems can help companies utilize them to their fullest potential.

The automation revolution is likely coming whether individual manufacturers and other industrial organizations are ready for it. Forecasts show the industrial robotics market hitting $24.4 billion by 2025.

Global Electronic Services repairs and services all types of industrial equipment from electronics and servo motors to industrial robotics. We fully load and function test all of the equipment we work on and stock thousands of parts to aid in repairs. You can request a quote here for industrial equipment repair or maintenance services.