As equipment ages and becomes unsupported by the manufacturer it is only a matter of time before the machine goes down and leaves the user scrambling to find a solution. Most often this solution is repair of the broken equipment, but there are some circumstances that can complicate things if you are not ready for them. Here are a few.

A Firmware Revision

Firmware is a piece of software that provides control of the basic functions of a devices hardware. Often when installing new equipment, troubleshooting existing problems, or just simply doing routine maintenance it is often a common practice to install the latest firmware revisions into the device. This can be very disastrous. The reason being is not all manufacturers plan for their equipment to be supported for all time, using the same types of software. As things change over the years and new replaces the old, so does the firmware. Loading a piece of firmware onto a device that does not support it can sometimes cause harm and not be a reversable process. It is advisable to have some thorough talks with technical support at the OEM before attempting such upgrades.

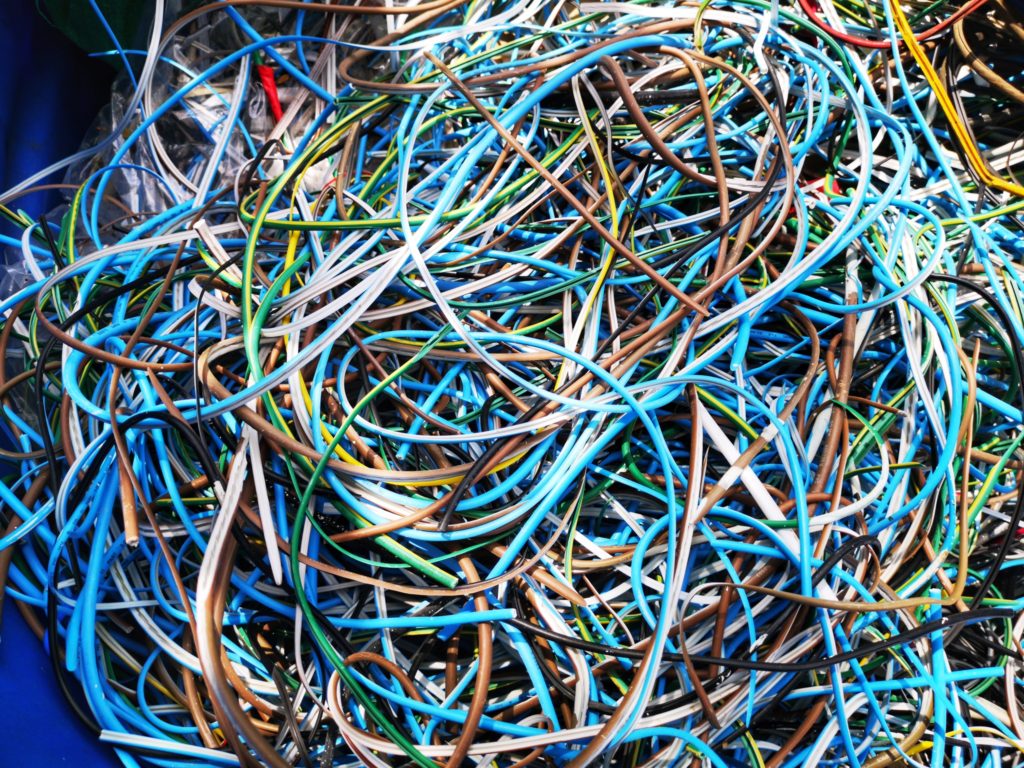

Unlabeled Wiring

In the case of machines with thousands of wires in the controls cabinets, usually there is a machine schematic included that explains where each goes. But if a machine is many years old, chances are at some point this document has become lost or misplaced which if the manufacturer of the machine does not support it or has gone out of business, getting a hold of these prints may be impossible. Moving even a few of these wires around and not properly labelling them can create a situation where you now have thousands of possible combinations and the way the machine was originally configured is now lost.

Control Membranes or Integrated Button Schemes

One of the more annoying problems older equipment faces are applications where the machine builder has set up a specific component, especially one that gets a lot of use, to not be replaceable should it fail. Some machines utilize custom keypads with a simple membrane that is printed at the factory. Once this membrane is worn out, it is not easily replaced as it is constructed as an overlay and glued on. Should a device like this failed, it is best to send it to a repair center that is can handle replacing buttons to a component level.

Be sure to visit us online at www.gesrepair.com or call us at 1-877-249-1701 to learn more about our services. We’re proud to offer Surplus, Complete Repair and Maintenance on all types of Industrial Electronics, Servo Motors, AC and DC Motors, Hydraulics and Pneumatics. Please subscribe to our YouTube page and Like Us on Facebook! Thank you!