Component parts become obsolete. You can’t avoid it. Diminishing natural resources, technological developments, and changing market demands make obsolescence inevitable.

Component parts become obsolete. You can’t avoid it. Diminishing natural resources, technological developments, and changing market demands make obsolescence inevitable.

But that doesn’t help plant and floor managers. If the parts are essential, obsolescence can be disastrous.

They’ll have to scramble to find replacements somewhere. They could search for cross-use parts that fit to succeed discontinued parts. If they can’t find suitable replacements, complete redesigns may be necessary, burdening the company with lengthy design and certification processes as well as slashing into sales.

So, what can you do to avoid being stung by a part discontinuation?

Pay attention to relevant notices

According to the JJS Manufacturing article, manufacturers will often send out some or all these notifications:

- Product change

- End of life

- Product discontinuation

- Last-time ship date

They also often post and alert you to these notices on their websites. Make sure someone in your organization tracks these notices so part discontinuations won’t come as surprises. If you have an assembly partner such as a contract electronics manufacturing company, employees there can track for you. Kitting and component verification companies also provide this service.

They also often post and alert you to these notices on their websites. Make sure someone in your organization tracks these notices so part discontinuations won’t come as surprises. If you have an assembly partner such as a contract electronics manufacturing company, employees there can track for you. Kitting and component verification companies also provide this service.

Keep in mind, however, manufacturers are notoriously unreliable in sending and posting notices. One way you can ensure you’re in the know is by subscribing to a service that aggregates parts data and provides it to subscribers through an online database. An obsolescence management service is another option.

Identify high-risk parts

As early as the design phase, you can identify parts prone to obsolescence, perhaps due to rare materials or source dependency on politically volatile regions, according to the Electronic Design article. When you identify high-risk parts early, you can buy and store as many of those parts as economically or logistically feasible. You can also plan for suitable crosses.

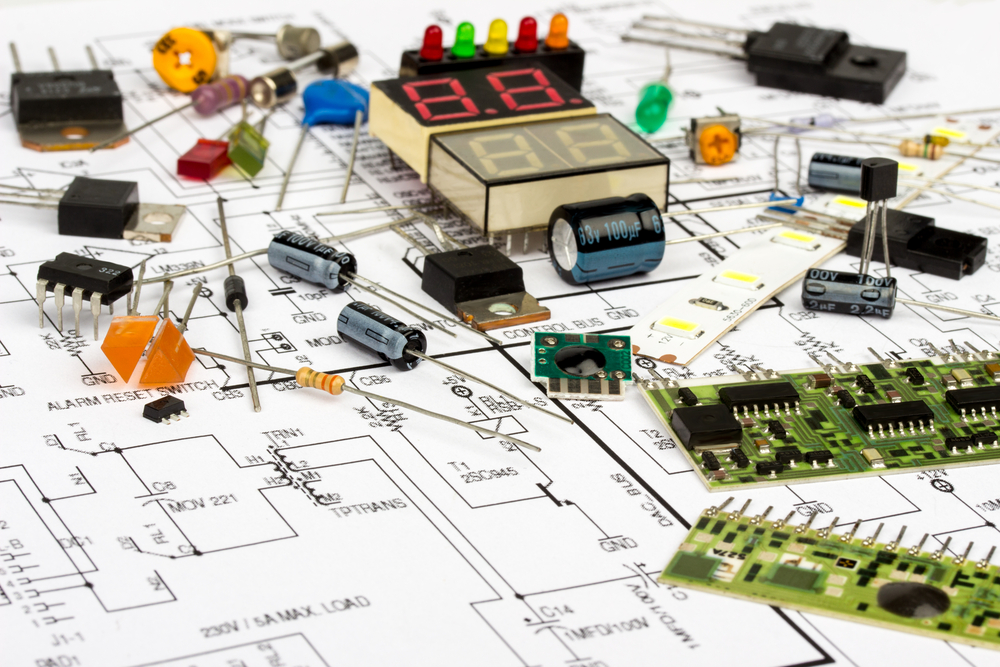

What do you do if your equipment becomes obsolete and you don’t even know what components are inside?

At Global Electronic Services, we specialize in repairing old and obsolete equipment and because we repair down to the component level, obsolete circuit boards or individual components that make up the inside of your equipment are no problem. Obsolete components are something we see everyday, but we have the ability to reverse engineer circuitry and cross components that are no longer available. We also stock millions of common failure components and complete surplus units, paying special attention to those headed to obsolescence. Our engineering team is ready to find a solution to your obsolete equipment.

Contact us or call 877.249.1701 for all your industrial electronic, servo motor, AC or DC motor, hydraulic, and pneumatic needs.