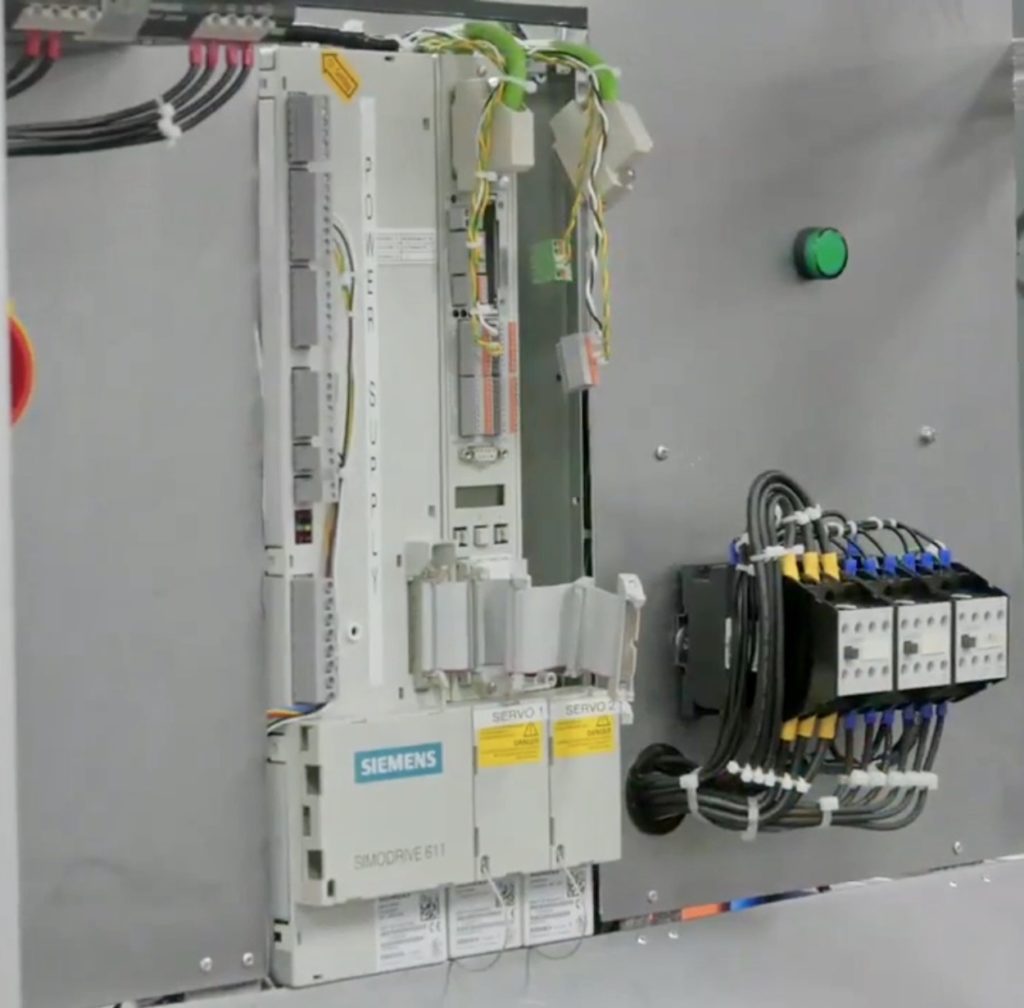

The Simodrive 611, introduced by the Siemens company as a flexible solution for machine tools, robotics and other servo applications, is now being phased out. As customers are being directed to the Sinamics S120 and other replacement options, more and more of the Simodrive Converter systems are being repaired by our service center than ever before.

Due to its robust design and quality of engineering, the Simodrive has become a favorite of our repair technicians on the bench. When they fail, they are very rarely non-repairable, which makes servicing the Simodrive system a great choice when compared to a costly replacement. This is tempered by the fact that often the damage is relegated to only one of several modules in the system and can be quickly isolated and repaired using our test stand. Here we will cover the top 3 common failures of the Simodrive 611 modules that we are now seeing as these modules begin to show their age.

#3 Power Supply Module Failure

The Simodrive Converter modules are outfitted with a dedicated power supply module that distributes voltage and current from the main power to the attached drive modules through a 600VDC link. This power supply module is truly the workhorse of the system. It suffers the most failures from facilities that have had a history of problems with their power distribution. Overvoltage, phase imbalance or even facility-wide brown-outs can stress an aging Simodrive System prematurely. What we see most commonly in these cases is within the capacitors found on the power board brought on by input power stress. Also within the supply module we see shorts occurring by zener diodes opening up from this same type of high current stress.

#2 Drive Module Failure

For each Drive Module connected to a motor, whether it be standard servo or spindle, we often see mechanical issues machine-side contribute most to their failure. As equipment ages, certain new failure modes start to creep up. For example, servo motor bearing failure can lead to a thermal run-off failure in the motor windings which can stress the load side of the drive module. The transistors that control output current to the motor are the number one replaced component in these situations. Other load side issues, such as mechanical jarring/jamming, bad/shorted cables or even improperly set machine parameters can cause a drive module failure.

#1 Environmental Failure

One great part of the Simodrive design is its ability to distribute cool air over all of it components. This is important due to the fact that the system is modular, which is a desirable trait to engineers wanting a relatively compact construction within the tight confines of a control cabinet. Whenever you have electronics so close together within a confined space you have to keep things cool. But over the years, as dust and other debris begin to collect on the internal fans, or even on internal board components, we start to see overheat failures. Rarely do we see just a fan go out on these modules. Often a fan failure is accompanied by overheated capacitors, resistors, triacs or other components.

While the Simodrive is heading towards becoming a legacy product, it will remain as one of the most utilized servo systems in many manufacturing facilities. Because of this, having a full test stand built in our test lab is key to successful repair. It allows our technicians to service these modules, install them in our test stand and fully test them as though they were in their own environment. With its reliable design, quality components and its modular design, the Simodrive 611 we know will be one of our technician’s favorite repairs for many years to come.

Please share your comments or questions with us below and be sure to visit www.gesrepair.com or call us at 1-877-249-1701 to learn more about our repair services. We’re proud to offer Complete Repair and Maintenance on all types of Industrial Electronics, Servo Motors, AC and DC Motors, Hydraulics and Pneumatics. Please subscribe to our Blog and our YouTube page and Like Us on Facebook! Thank you!