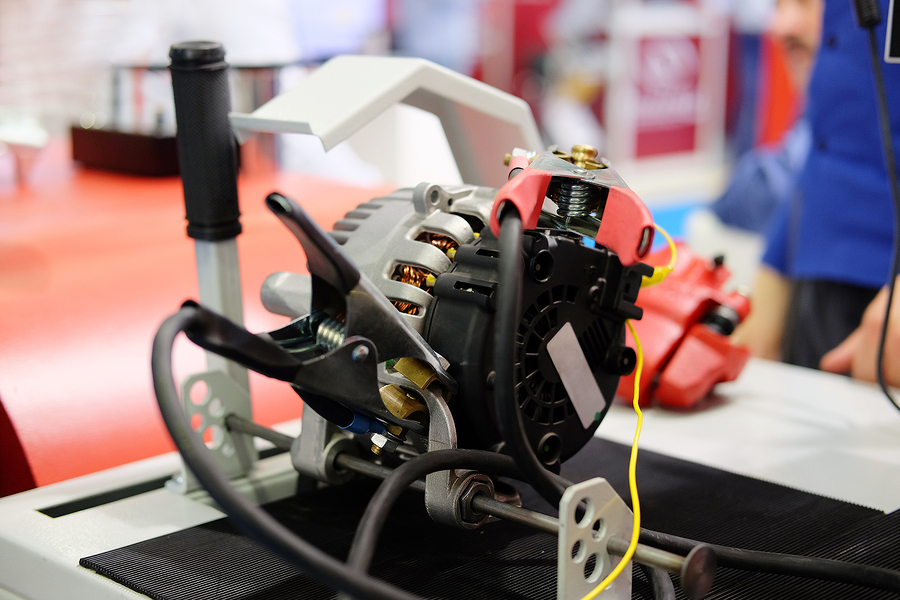

Most manufacturers recommend regular equipment maintenance — not only to guard against catastrophic failures but also to keep equipment running ideally throughout its lifespan. Some simple maintenance operations include lubricating moving parts, inspecting machinery, and cleaning it all regularly.

While many manufacturers schedule machine maintenance to prevent failure, some — under certain situations — operate on a “run-to-failure” maintenance plan. This strategy, to run machines until they fail, makes sense for many reasons.

Run to failure can be a reasonable alternative if operators don’t utilize equipment enough to justify maintenance costs. For example, machine shop employees provide cutting and shaping as their primary services; metal polishing is a secondary service. If the polisher breaks down, shop staff can polish by hand until a repair or replacement arrives. And, as polishing is not a core service, they’d lose little productivity.

In some cases, equipment failure provides invaluable training for staff members, especially in preparation for emergency cases. For instance, one plant has three backup generators to take over in case of an outage. Plant personnel test these generators periodically by shutting down power and allowing the generators to cycle on.

As they rarely use the generators, a regularly scheduled maintenance program is not cost-effective. And, if a generator fails during a planned shutdown, staff have an opportunity to practice their responses. They can attempt to manually sync generators, and management provides detailed instructions on how do so in case of an actual emergency. Failure during a practice run helps staff better prepare without jeopardizing the plant line schedule.

Another consideration for a run-to-failure maintenance plan is maintenance costs versus replacement costs. Personnel should evaluate each equipment piece to determine if maintenance costs exceed replacement costs. Just as a car insurer weighs whether to repair or replace your wrecked vehicle based on its current value, plant managers should determine equipment fair market value and acceptable loss. In the long run, it may simply be more cost-effective to replace equipment rather than maintain and repair it.

Another consideration for a run-to-failure maintenance plan is maintenance costs versus replacement costs. Personnel should evaluate each equipment piece to determine if maintenance costs exceed replacement costs. Just as a car insurer weighs whether to repair or replace your wrecked vehicle based on its current value, plant managers should determine equipment fair market value and acceptable loss. In the long run, it may simply be more cost-effective to replace equipment rather than maintain and repair it.

Of course, the strongest argument against a run-to-failure maintenance strategy is the worst-case scenario. Equipment failure can cause major service and productivity disruptions. If predictive or preventive maintenance exceeds repair or replacement costs, lost time, lost productivity, and unmet deadlines, it makes sense to employ a run-to-failure strategy.