Additive manufacturing underwent tremendous growth last year. But what are its advantages — and what challenges remain before we see more widespread use?

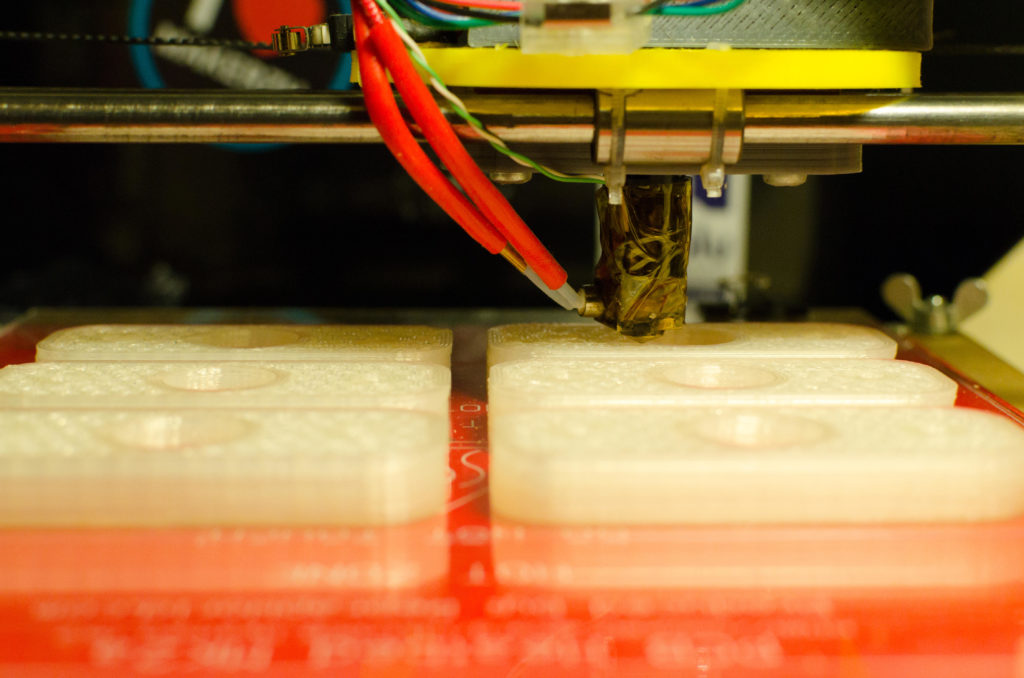

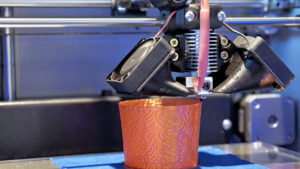

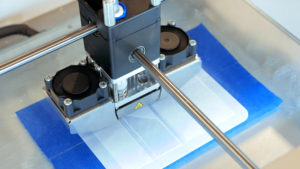

Additive manufacturing is regularly referred to as 3-D printing. The process starts with a digital design before the printer layers ultrathin material to form the object in the design. The materials — such as plastics, metals, and composites — vary, so additive manufacturing is used in a number of applications from medical implants to industrial gas engines and wind turbine blades.

Pros

Additive manufacturing improves efficiency, lowers costs, and enhances final product quality and design.

Additive manufacturing improves efficiency, lowers costs, and enhances final product quality and design.

In traditional manufacturing, workers chop, chisel, or otherwise cut material away from solid material blocks to form finished products, leaving unused excess waste. Wasted material equals wasted money and resources, but additive manufacturing uses less by allowing the printer to build material upon itself, creating virtually no waste.

Similarly, manufacturers use the method to restore parts and products, creating a new green economy based on remanufacturing. They produce parts more cheaply and in smaller batches, lowering maintenance costs and extending machine longevity.

For highly complex objects and components, additive manufacturing is invaluable. It allows you to build a single object from the bottom up by layering material upon material — instead of welding joints. You no longer need different components, customized tools, or external suppliers. By automating production processes, you can skip right from design to production.

Additive manufacturing also makes tweaking end products more efficient. Engineers can adjust designs on computers, enabling them to build or refine new components and complex systems that would otherwise require costly modeling and molds.

Cons

There are drawbacks as numerous sectors are still adapting to 3-D printing before its use becomes more widespread. Additive manufacturing is relatively expensive and better suited to smaller production scales like creating spare parts.

There are drawbacks as numerous sectors are still adapting to 3-D printing before its use becomes more widespread. Additive manufacturing is relatively expensive and better suited to smaller production scales like creating spare parts.

Products easily made with traditional methods will not yet benefit from additive manufacturing. Especially when it comes to large-scale production, traditional manufacturing carries less cost.

While it may not yet be the most cost-effective way to produce products in large quantities, the technology is advancing very rapidly and is here to stay.

At Global Electronic Services, we’re adapting to 3-D printing alongside manufacturers around the globe. Contact us online or call 877.249.1701 for all your industrial electronic, servo, AC and DC motor, hydraulic, and pneumatic needs.

At Global Electronic Services, we’re adapting to 3-D printing alongside manufacturers around the globe. Contact us online or call 877.249.1701 for all your industrial electronic, servo, AC and DC motor, hydraulic, and pneumatic needs.