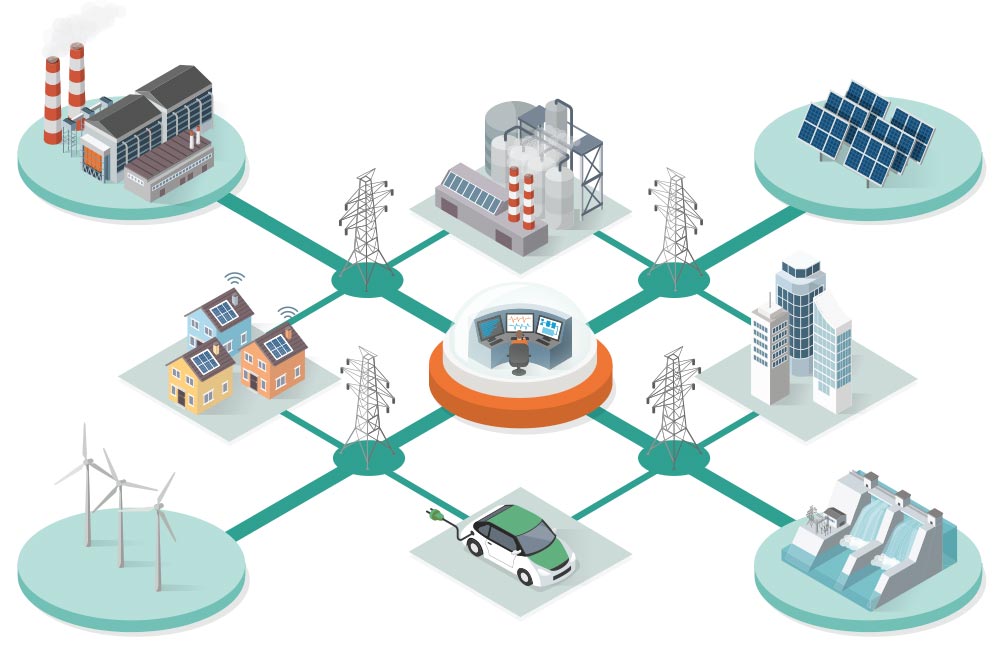

Traditionally, large-scale centralized power plants have been a primary energy distribution method. The current trend in power generation, though, favors a less centralized model.

Today, distributed power technologies — combined heat and power (CHP) plants, fuel cells, hybrid power systems like diesel and gas reciprocating engines, microturbines, photovoltaic systems — that provide power at or near the point of use are becoming mainstream. Manufacturers have the opportunity to turn to on-premise power generation models to save money.

Distributed power provides several advantages over conventional large-scale centralized plants. Large-scale transmissions waste energy due to aging equipment and growing congestion, resulting in poor power quality due to voltage or electrical flow fluctuations. Your home electric bill likely reflects this inconsistent and unreliable schedule.

Generating power locally using distributed systems provides higher-quality power and “peak shaving” options. Peak shaving refers to synchronizing generator frequencies with fluctuations in the grid to reduce the amount of plant energy users consume during peak demand hours. Those generating surplus power can sell it back to the grid, which can yield significant returns during peak demand. Peak shaving generators can also provide backup power in case of grid outages.

According to the Baldor article, switching to distributed energy technologies can provide a return on investment within three to five years. Because generators can last well over 30 years, reducing your utility costs during peak demand can result in long-term savings. For example, Baldor Electric Company executives added just three 140-kW peak shaving generators as well as paralleling switchgear and monitoring equipment to the Westville Oklahoma motor plant. These upgrades save them over $100,000 annually from peak shaving.

You can eliminate additional expenses at your plant by using cogeneration technologies, which allow business leaders to utilize the heat they create during generation that they’d otherwise waste in separate electricity and heat plants. Such systems are especially useful in industries requiring large heat inputs, like oil refining and steel manufacturing.

You can eliminate additional expenses at your plant by using cogeneration technologies, which allow business leaders to utilize the heat they create during generation that they’d otherwise waste in separate electricity and heat plants. Such systems are especially useful in industries requiring large heat inputs, like oil refining and steel manufacturing.

In addition to generators, hydrogen fuel cells are also a promising distributed energy technology. Though still under development in the automotive and aerospace industries, hydrogen fuel cells are widely used in many industrial, manufacturing, and supply chain applications. Many North American Wal-Mart distribution centers, for example, use fuel cells to power forklifts. This isn’t just a clean energy alternative but also provides continuous power to forklifts and eliminates the need to constantly replace batteries.

Are you ready for distributed technology?