Of all the failure modes, the most preventable in our line of work is contamination. Dirt, dust, debris, oil and electronics simply do not mix. There are two main effects that contamination has on the lifespan of delicate circuitry.

- Insulation – When you add a layer of debris to a printed circuit board you are essentially adding a layer of heat insulating matter to the substrate of the board. As the board draws current, the heat generated cannot properly dissipate across the surface of the substrate material. This will lead to a thermal runoff event that will likely result in a catastrophic failure in the key components on the board.

- Contamination – When there is a contamination event that leads to electrical connections where electrical connections are not supposed to be. Namely a short circuit fault where the contaminant, usually water, serves as a bridge to current that damages other components in-circuit.

On many occasions when we cite this type of failure on a work order, maintenance personnel will want to know how this type of failure can be prevented. The major question being…

How can I remove contaminants from my electronics without damaging them?

Physically remove the debris

The most common type of debris we see in the service center is dust. The reason for this is simple. The anode of any high voltage circuit will act as an attractor to particles in the air and naturally attract dust.  The positively charged electrons will attract negatively charges floating particles resulting in debris accumulating on whatever charged surface is present. This is especially prevalent in older CRT (cathode ray tube) screens where a high amount of voltage is present. The first step is to remove this debris.

The positively charged electrons will attract negatively charges floating particles resulting in debris accumulating on whatever charged surface is present. This is especially prevalent in older CRT (cathode ray tube) screens where a high amount of voltage is present. The first step is to remove this debris.

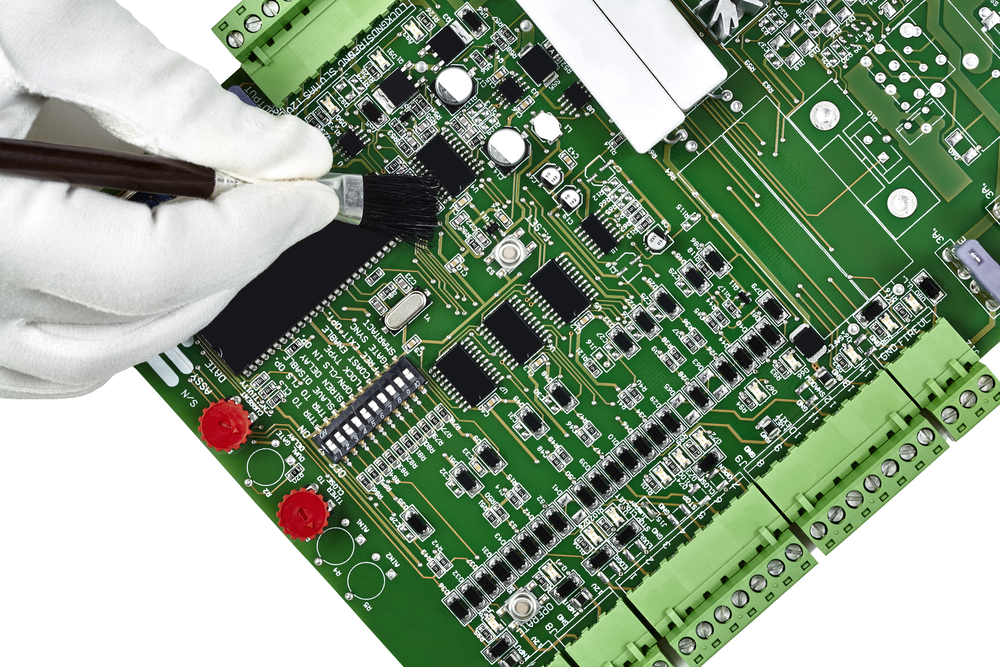

When we remove dust from a piece of circuitry we like to use natural fibers. The reason for this is that we see the natural fiber brushes tend to generate a lot less static electricity which can harm delicate integrated circuits such as processors and microcontrollers. In addition, they wear a lot less quickly and tend to be easier to wash between uses. Take a natural fiber brush and gently “pat” down the debris. Use compressed air to knock loose and blast away any dust that you may find.

Chemically remove residue

After physically removing any contaminate, you might be left with residue such as grease, resin, oil or other substance that cannot simply be knocked off by a good scrubbing. The next step you need to employ is to chemically wash the circuit. There are two basic types of chemicals best suited to this purpose, degreaser and solvent.

- Degreaser – This is great for removing any oil based contaminates but it is important you pick one designed for use with electronics. There are two factors in play: first is a high rate of evaporation. This will insure that the chemical will be fully gone by the time you power the device. The second is low residue build-up. If the chemical leaves a residue, it will just make the problem worse in the future as dust particles bind to what’s left on the surface of the board.

- Solvents – They are very good at cleaning circuit boards as well. Isopropyl alcohol is a favorite due to its high evaporation rate, low toxicity and non-corrosive nature. This is commonly a last step to the cleaning process. Combining Isopropyl alcohol and compress air can be a great combination to ridding any surface pollution on the board.

There you have it, some tips on cleaning PCB’s to insure a full and healthy lifespan. But if you do have a contamination related failure, we can help! Be sure to visit us online at www.gesrepair.com or call us at 1-877-249-1701 to learn more about our services. We’re proud to offer Surplus, Complete Repair and Maintenance on all types of Industrial Electronics, Servo Motors, AC and DC Motors, Hydraulics and Pneumatics. Please subscribe to our YouTube page and Like Us on Facebook! Thank you! Thank you!

Hi Chris ! Thanks for sharing this. But I found, it is still difficult to clean a circuit board for me. Maybe because i am not from electronics field. Also surely your blog helped me up to some extent.