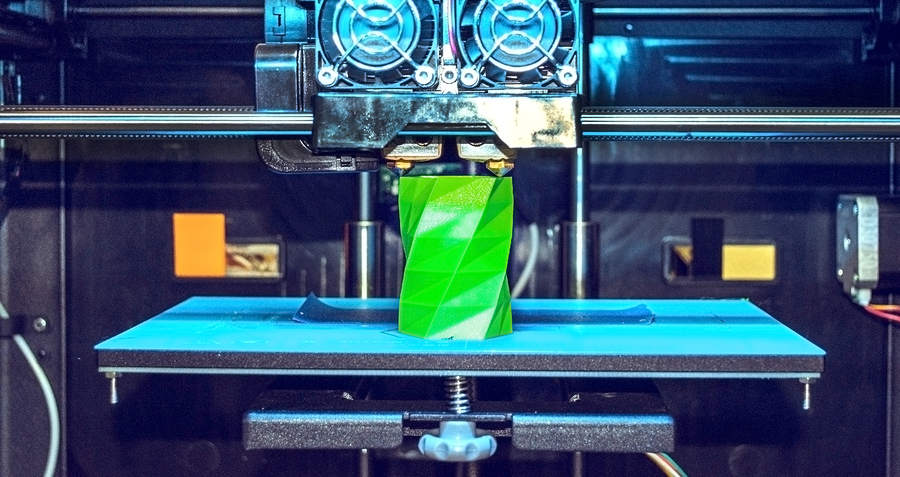

While 3-D printers aren’t yet becoming commonplace in American homes they way TVs and computers have, they’re beginning to become more mainstream in manufacturing processes. For those considering implementing additive manufacturing technology into their production, it’s important to consider more than just the printer make, model, and capabilities. What do they need to know about open- and closed-source 3-D printing — especially new filament releases — and why does it matter?

Closed-source

In closed-source 3-D printing, printer companies sell filament specific to their printers. With such proprietary products, companies can charge a premium for their filaments. This increases the lifetime cost of the printer as well as that of the individual printed pieces and the final products.

In closed-source 3-D printing, printer companies sell filament specific to their printers. With such proprietary products, companies can charge a premium for their filaments. This increases the lifetime cost of the printer as well as that of the individual printed pieces and the final products.

Open-source

Similar to open-source printer software and designs, some filament producers began making more universal products. This open-source filament combats the issues of high proprietary and finished product costs. And the push for non-proprietary products also enables enhanced filament recycling opportunities, meaning filament companies can include polymer recycling codes. This is especially important for ensuring the filament has the correct properties and for those who do in-house polymer recycling.

When manufacturers have access to information on the filament quality, how the filament itself was manufactured, colors, parameters, and more, they have more ability to control their finished products. Still, they must consider whether their printers are equipped to print using open-source filament as opposed to closed-source as some manufacturers void their printer warranties and guarantees when users introduce them to filament not made specifically for those printers.

Risk and opportunity

While open-source creates many opportunities for manufacturers to know exactly what their filament is made of for production and recycling, some sectors are losing business as a result. Toy manufacturers, for example, are seeing open-source 3-D printing as a disruptor. At-home 3-D printing greatly reduces the price for simple toys compared to name-brand manufacturers’ products, many of which produce their toys with subtractive manufacturing.

While open-source creates many opportunities for manufacturers to know exactly what their filament is made of for production and recycling, some sectors are losing business as a result. Toy manufacturers, for example, are seeing open-source 3-D printing as a disruptor. At-home 3-D printing greatly reduces the price for simple toys compared to name-brand manufacturers’ products, many of which produce their toys with subtractive manufacturing.

Will this become a trend in industrial manufacturing? It’s not likely as most in-home 3-D printers can only produce items on a small scale and aren’t as technologically advanced as industrial printers. Plus, industrial manufacturing printer ownership is cost-prohibitive to the vast majority of American families who wouldn’t have the safety precautions or space necessary to house and use them. They likely wouldn’t have much use for the products these printers can produce, either.

While open-source might not be a boon to those who create small consumer goods, manufacturing professionals interested in the technology — whether they use it on the job or not — could save pennies in the long run by producing their own building blocks and other household items with consumer 3-D printers. For now, it appears large-item manufacturers invested in additive manufacturing aren’t at risk and small-scale 3-D printing is best left to those who can afford at-home printers and those who work in network television.