In the age of smartphones, consumers want it their way, they want it all — and they want it now. As more industries move to on-demand delivery, manufacturing needs to keep up. But how can those in the industry move to this level of need-it-now personalization, and what are the benefits — and drawbacks — of moving to this type of model?

Technology advances

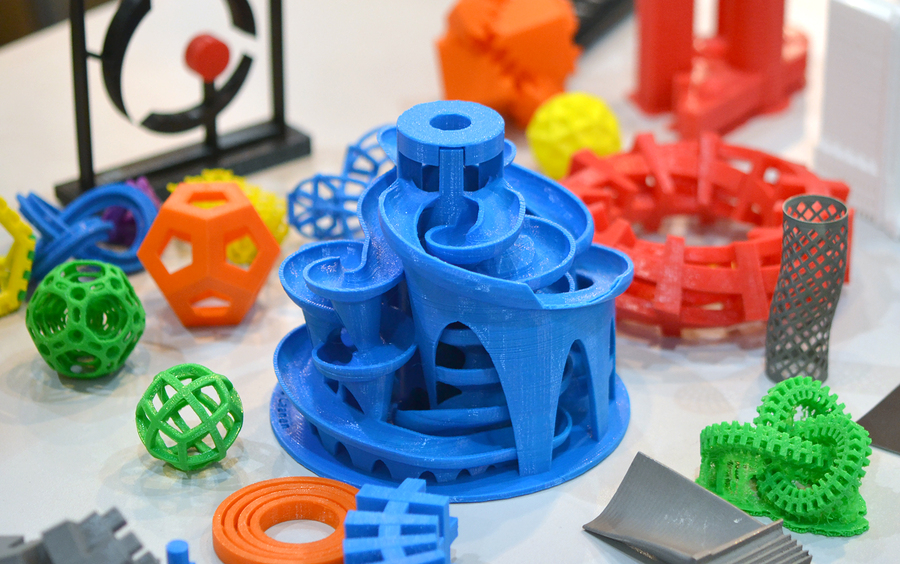

As changes in manufacturing technology bring artificial intelligence (AI), additive manufacturing, and more to the industry, they allow for product personalization — the new norm compared to past standardization. And although personalization tends to be more expensive, these tech advancements have allowed manufacturers to focus more on consumers and their needs at reduced costs — even in smaller batches.

Personalization

From private jet interiors to shoes, the market seems to be shifting toward consumers who are willing to take the time to design — and pay for — both personalization and immediacy. While original equipment manufacturers produce jet aircraft bodies, buyers can choose interior elements and design their cabins as they see fit. Not only does this give them more control over end products but it also adds to the luxury of finished jets.

Nike is taking a similar approach with an on-demand shoe solution that puts custom kicks into designers’ hands “in less than 90 minutes” from planning to finished product. While the company has long offered custom design options, the on-demand aspect is new for the Nike Presto X shoes. And, while individual pairs of shoes are much smaller-scale than many manufacturing plant offerings, Nike also incorporates AI to project options onto designers’ shoes, showing them how they’ll look — and fit.

Luxury

While it’s clear private jets command high prices, the same will likely be true for custom shoes — if or when Nike makes them available to the general public — as well as other custom products. And even though technology is speeding up the production of custom-manufactured goods, these products will likely continue to cost a premium as it’s pricier for manufacturers to keep custom stock items on hand. These goods also require manufacturers to be closer to consumers: Without consumers being physically present to design and receive their custom shoes, for example, delivery time could otherwise be much more drawn out.

Could this new movement be a boon to manufacturers? In some cases, especially for those with the ability to invest in up-and-coming technologies, readiness to lead the pack, and physical space for these capabilities — including storage for raw materials —can make them reality.