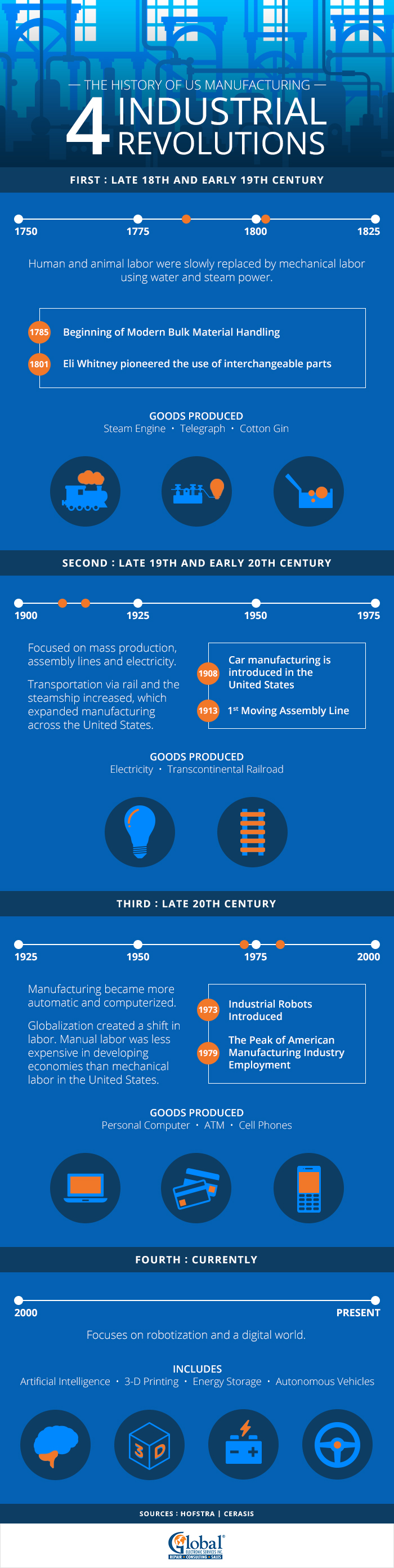

The history of U.S. manufacturing goes back more than 200 years. Since its start in the 1700s, a great deal has happened, from the introduction of the moving assembly line to the creation of autonomous vehicles. Ready to learn more about the four industrial revolutions and their impact on manufacturing?

The First Industrial Revolution

During the early years of the United States is when the first industrial revolution began — and it lasted well into the early 19th century. Samuel Slater, who brought over manufacturing technologies from Britain and founded the first cotton mill in the U.S., is often credited with spurring this industrial boom.

While this era of U.S. manufacturing’s history was more confined to the Northeast, it signaled the shift from manual labor to mechanical labor. Instead of people, water and steam-powered cotton mills, trains and more. The concentration of manufacturing in the Northeast also promoted the development of infrastructure, like canals and railroads.

Noted accomplishments during this time include the cotton gin, telegraph and steam engine. The first industrial revolution is also credited with the beginning of modern bulk material handling, as well as the start of using interchangeable parts.

The Second Industrial Revolution

Amid the Reconstruction period, which followed the American Civil War, is when the second of the four industrial revolutions began. This era lasted into the early 20th century. Mass production and the launch of electricity as an industry, as well as the expansion of the U.S. transportation system, characterize this era.

Mass production is often a term associated with Henry Ford, who installed one of the first moving assembly lines for manufacturing cars in the U.S. With faster assembly times — which relied on interchangeable parts — Ford was able to lower the price of his Model T cars, which soon became affordable for even his plant employees.

Another accomplishment of this era is the growth of manufacturing across the U.S. With the building of the transcontinental railroad, companies could establish more plants outside the Northeast, thus bringing the industrial era to communities in the Midwest and beyond.

The Third Industrial Revolution

While built on the foundation of the earlier industrial revolutions, the third signified another shift in labor. This period of history in U.S. manufacturing is more recent and familiar to companies and even consumers, as it began in the late 20th century. It’s when automation, globalization and computerization joined the manufacturing industry.

Globalization, which resulted from trade liberalization, played a substantial role during this time. In combination with lower transport costs, as well as decreased labor costs in developing countries, many manufacturers in the U.S. outsourced labor to these emerging economies. As a result, the third of the four industrial revolutions is considered the peak of employment in the American manufacturing industry.

While some manufacturing plants in the U.S. shut down during this time, the period did introduce the personal computer and cellphones, as well as ATMs and industrial robots. It also set the stage for the fourth industrial revolution.

The Fourth Industrial Revolution

Today’s modern world is the fourth industrial revolution, which began at the start of the 21st century. The introduction of robotics and automation, which were d eveloped during the previous era, are the focus of today’s industrial revolution.

Robotics now centers on creating industrial machines that can perform simple and complex procedures, as well as adapt to changes in these tasks. As a result, robots are becoming as flexible as manual human labor, which is rebalancing the input costs of manufacturers.

Ongoing developments of this period include artificial intelligence and autonomous vehicles, as well as energy storage and 3-D printing, all of which are bringing new changes to the daily lives of companies and end users across the world.

Where will the next industrial revolution take us? Looking back on the history of U.S. manufacturing, especially the most recent manufacturing eras, it’s possible the next period will continue to develop digital and robotic technologies that further automate simple and complex manufacturing processes.

Learn more about our industrial services and repairs for electronics, hydraulics, pneumatics and more by contacting Global Electronic Services today.