Over the past 20 years, the U.S. has lost approximately 25% of its manufacturing plants as well as a third of its manufacturing jobs. Even so, the U.S. still ranks as the second-highest global producer of manufactured goods. The sector has the potential to grow exponentially, but manufacturers must adapt and embrace the new, digitally based manufacturing landscape.

Current state of U.S. manufacturing jobs

According to a Deloitte study, U.S. manufacturers will need to fill an estimated 3.4 million jobs over the next 10 years. However, as many as two million of those jobs will not be filled due to a lack of skilled workers.

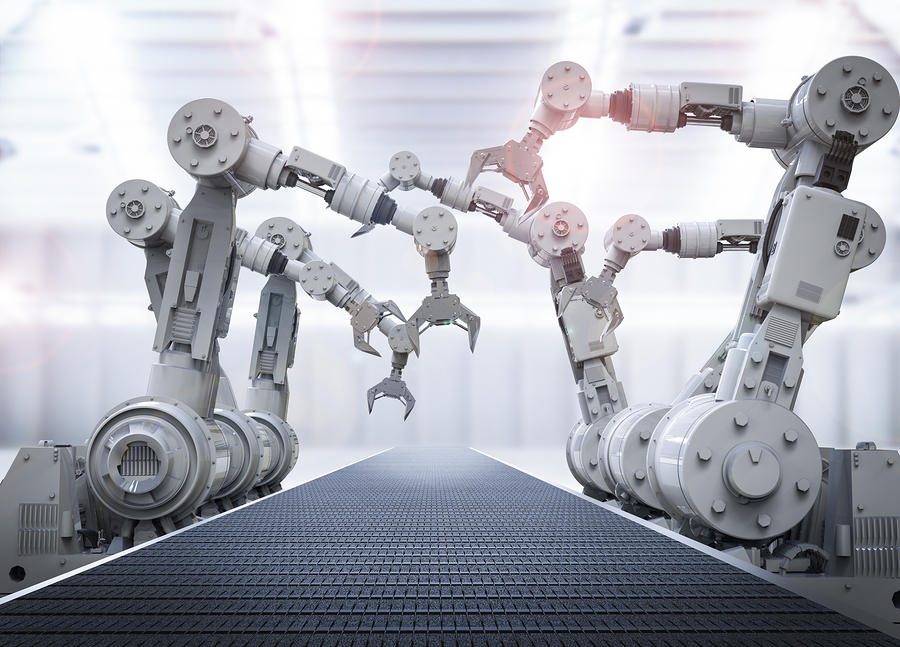

To be competitive in today’s world, manufacturers need updated, technologically driven plants where workers run automatic, digital, and robotic systems. The days of standing in assembly lines and simply pressing buttons to run single machines are disappearing.

Today’s workers need technical and digital know-how. They need to be able to read digital displays quickly and efficiently, manage several machines at once using a control panel, and be able to use online cloud-based information repositories. They also need to be able to think critically, adapt to new situations seamlessly, solve complex problems easily, as well as read, write, and communicate effectively.

This new face of manufacturing is referred to as Industry 4.0 or the Fourth Industrial Revolution. U.S. manufacturers should embrace the new technologically based environments Industry 4.0 is ushering in. By modernizing their plants and utilizing advanced digital systems such as 3-D printing and the Internet of Things, the U.S. manufacturing sector could increase in value by approximately 25% by 2025.

What are manufacturers doing to grow their workforces — and output?

As a manufacturing plant leader, how do you find the skilled workers you need? It is certainly not practical for every worker to obtain a college education. Even if all your employees had degrees, they would still need to continue their educations to keep up with the fast pace of technological advancements.

Many manufacturers are already taking action by teaming up with community college leaders, creating apprenticeship programs, and implementing various training programs in their workplaces.

For example, laid-off coal workers in Eastern Kentucky now have the opportunity to learn crucial Industry 4.0 skills so they can start new careers in manufacturing. An instructional program offered by eKentucky Advanced Manufacturing Institute provides training and certification in just 15 weeks.

For example, laid-off coal workers in Eastern Kentucky now have the opportunity to learn crucial Industry 4.0 skills so they can start new careers in manufacturing. An instructional program offered by eKentucky Advanced Manufacturing Institute provides training and certification in just 15 weeks.

Implementing new or using existing online training programs can also be a beneficial, cost-effective way to train manufacturers in necessary skills. For example, leaders at Tenaris, global steel pipe and energy-related industrial equipment manufacturers, created their own online university called Tenaris University. They offer online courses such as “Introduction to Steel” and “Introduction to Computer Numerical Control” to train manufacturing employees and screen potential applicants.

So, what is next for manufacturers? For most industry professionals, it may be imperative they seize opportunities to further their educations and keep updated with rapid technology changes in the sector. Those interested in beginning careers in manufacturing will likely need the same level of knowledge, whether they obtain it on their own through educational programs or land positions with manufacturers who offer company-sponsored training.