On-the-job training and competitive skills have always been valuable to those learning their trades, and automobile assembly and engineering are no exceptions. However, with manufacturers increasingly using robotics and computing in the automotive industry, what can individual facility employees and their employers do to navigate? BMW, Siemens, and Clemson University leaders are starting with education.

A research center like never before

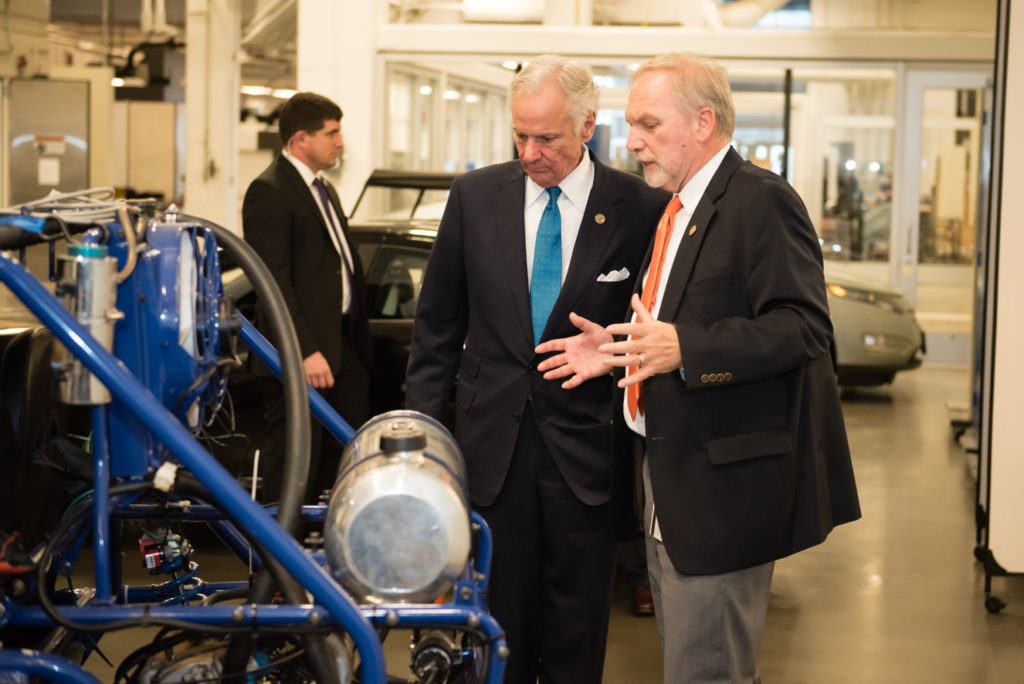

Leaders of Clemson University International Center for Automotive Research teamed up with Siemens Manufacturing and BMW executives to provide solutions to these problems for students and industry insiders alike with their new Vehicle Assembly Center. Their goals for the center are to bring together industry experts, researchers, and students like never before to collaborate and discover ways to advance the automotive manufacturing industry.

- The center, which opened in mid-February 2018 in Greenville, South Carolina, boasts 4,000 square feet, a complete three-station automobile assembly line, a robotics center, autonomous factory vehicles, and labs for embedded devices as well as subassembly.

- The new center will also allow technical students, undergraduate, and graduate students from Greenville Technical College and Clemson University to collaborate with one another, thus enhancing the learning process. It will also allow industry professionals to work with students from both institutions.

- Manufacturing training programs at the new center will enable future engineers and technicians to learn new skills using hands-on opportunities through a continuous production cycle. Here, students will have the chance to learn to work with the pressures they’d likely face in real facilities via the simulated environment. This is also the first facility to bring together the industry, a technical college, and a research university for collaborative projects.

A range of projects and skills

Researchers and industry professionals from BMW and Siemens will work with students on ways to make the most of today’s automotive manufacturing tech and improve future assembly lines via industry-based perspectives. Many Clemson researchers will come with a focus on engineering while students from Greenville Technical College will focus on manufacturing training. In today’s automotive industry, those in computing, engineering, and manufacturing work together toward a single goal: integrating humans with automation.

The future

Automotive engineering and manufacturing are part of an evolving industry rife with competition. The center will provide an example and model for other educational facilities to follow in the future, thus enhancing the essential human aspect in auto manufacturing. It could also boost the South Carolinian economy by attracting employers seeking skilled workers with comprehensive skill sets.

With innovative facilities like the Vehicle Assembly Center, vehicle manufacturing innovation is likely to continue as such partnerships provide manufacturers access to trained engineers and technicians. In fact, the ability to hire professionals with this type of hands-on training could slow and eventually end the skills gap in this industry sector. How? These future technicians will be better able to keep pace with new developments and help their employers remain competitive.

Through the Vehicle Assembly Center, BMW, Siemens, and Clemson University leaders aim to train next-generation engineers and technicians with cutting-edge knowledge in information and systems integration. The partnership also offers students a sense of on-the-job teamwork and better preparation for their careers than ever before. The new facility will likely help students and employers move forward in the growing automotive manufacturing industry, providing new skills and solutions for years to come.