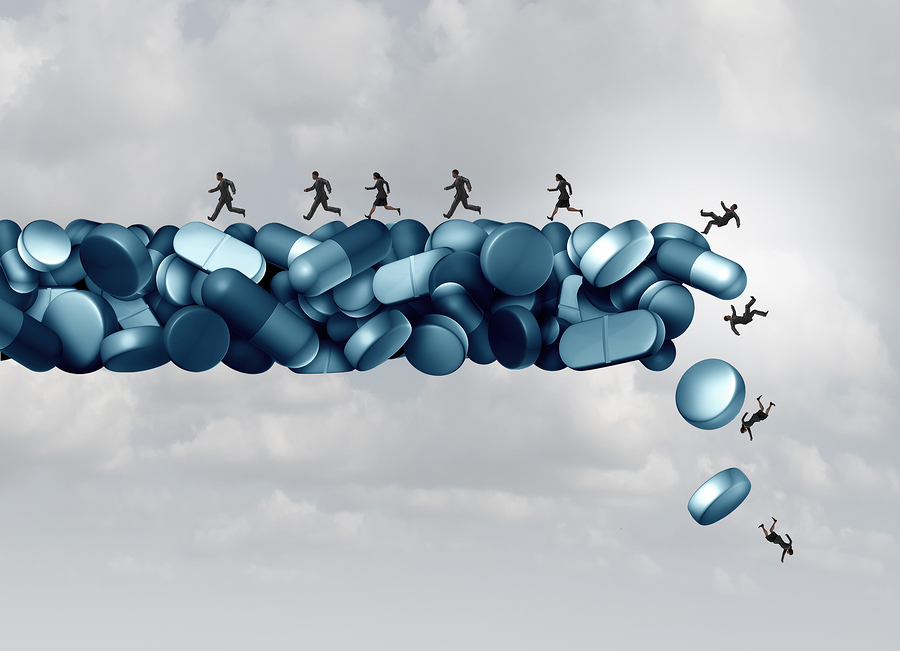

Drug use and physical fitness are often framed as individual issues with individualistic solutions, but the reality is both have tremendous impacts on society’s collective well-being. To see a prime example of this interconnectivity, look no further than the manufacturing industry.

Opioids: Decreased labor participation, increased risks

The opioid crisis, in particular, is hitting the American manufacturing segment very hard. Areas with the highest number of opioid prescriptions also have lower labor participation rates. This is particularly worrisome because areas with the highest opioid risk levels are also areas with the largest manufacturing workforces. To put it another way, as the opioid crisis continues to spread, areas with the most need for skilled manufacturing workforces are going to be in the worst positions to find qualified workers.

These are not minimal concerns. One study found that nearly half of men in prime working age who are out of the workforce are taking prescription pain medication on a daily basis. Some manufacturers report up to 40% of accepted applicants fail their pre-employment drug screenings because of opioid use and abuse. What was once a fringe annoyance all manufacturers knew they would occasionally see in their hiring processes has become a major obstacle to finding an adequate workforce.

Fitness: Demanding jobs, fewer qualified

In addition to the drug crisis, there is also a pronounced “fitness gap” in the manufacturing workforce. Manufacturing jobs are physically demanding: They often require long hours of standing, twisting, lifting, pulling, and pushing — tasks that call upon a range of muscle groups as well as require physical stamina. In addition, these jobs are mentally taxing: They require workers with the mental resilience to withstand productivity expectations and other pressures as well as to face such challenges with a healthy work ethic.

The communities surrounding manufacturing areas tend to have poorer overall health habits, and this is likely one fitness gap source. These communities tend to be located in less urbanized areas, giving members of the community less access to key resources. The communities also tend to be hardest hit by the opioid epidemic and by social dysfunction such as violence. The lack of access to quality food options and physical fitness facilities further exacerbates the overall health disparities, leaving manufacturers with fewer qualified applicants to draw upon.

What can manufacturers do?

While these are multi-faceted problems, a multi-pronged approach from many key entities could solve them. In fact, manufacturers in particular can take action to help alleviate problems the opioid crisis and fitness gap cause.

- Be aware — It can be tempting to ignore these statistics and continue operating as if the opioid crisis and health disparities are outliers in an otherwise healthy workforce. However, ignoring reality doesn’t change it. Being upfront about the problem is the first step toward finding sustainable and meaningful solutions.

- Focus on wellness — Robust wellness programs that offer direct information about the risks of opioid use can help address the problem at its source. Those that include available assistance to employees struggling with addiction and help them find alternative pain management techniques can be especially effective. Wellness programs that offer incentives and subsidies for fitness efforts are also a way to change the culture surrounding physical health. Finally, making sure employees have access to health care options that include mental health resources can more adequately meet their needs — and manufacturers’.

- Spend wisely — Many manufacturers have begun investing in philanthropic programs aimed at addressing these issues. The best use of these resources, though, ensure the funds are going to programs that directly impact the community with proven efficacy. Often, funding public health programs is the best way to make an immediate and sustained positive impact.

Ensuring a healthy and competent workforce is a key part of manufacturing success. While manufacturers can’t eliminate these problems on their own, taking steps toward educating and offering services to current employees is a way to initiate change in individual companies and facilities.