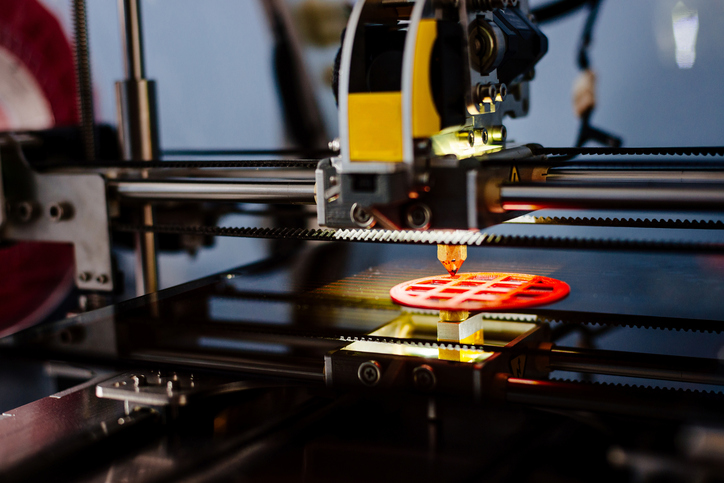

While it’s certainly a sign of the future, additive manufacturing’s adoption rate has been slow to catch on in various industries. The United Parcel Service shows 3D printing as a market of more than $12 billion with projections to increase to over $20 in the next two years, but the practice represents less than a half of a percentage point of worldwide manufacturing. We previously discussed some pros and cons of 3D printing, but let’s look in to a few reasons why companies seem to be bullish on additive manufacturing.

Mass production is definitely one of the biggest hurdles for additive manufacturing. By design, 3D printing equipment works in limited, small-scale batches, which are generally customized and not applicable to an entire range of products. Most manufacturers are looking for speed and repeatability in their production line, with heavy time constraints limited how long they can accommodate for slower lead times.

Its impact is still uncertain in several industries. From company executives down the chain, there’s widespread uncertainty as to whether or not additive manufacturing is a company priority and what its key benefits are in place of traditional manufacturing techniques.

Companies aren’t certain they’ll be able to hire the right talent. Understandably so, a new technology and entirely new way of doing business requires different skills and a different understanding of technology. Finding the right people to manage those systems has businesses worried they’d be at a loss if they adopted new tech with no one to maintain it.

Repeatability isn’t certain for many printers. There are currently issues with printers producing different finished products despite no changes being made to the printer itself. For companies that rely on consistent, uniform products, that uncertainty simply can’t be tolerated.

With several companies focusing on the bottom line of costs vs. revenue, it’s reasonable to see why 3D printing is still in its infant stages. The costs of initial startup, requirements for smaller, customized batches, and uneven adoption rates are just a few factors currently holding additive manufacturing back. Its viability is certainly understood and its use is likely to skyrocket before long, but not until developers find a way to diversify its viability for smaller companies looking for speed and repeatability. In additive manufacturing’s defense, the technology is rapidly improving. That same UPS report details plans for printer speed to increase by nearly 90% in the next five years with decentralization of logistical networks speeding up the supply chain and cutting costs.

What do you think of 3D printing and its implementation in manufacturing? Is your business currently using it with plans to expand? Let us know in the comments below.