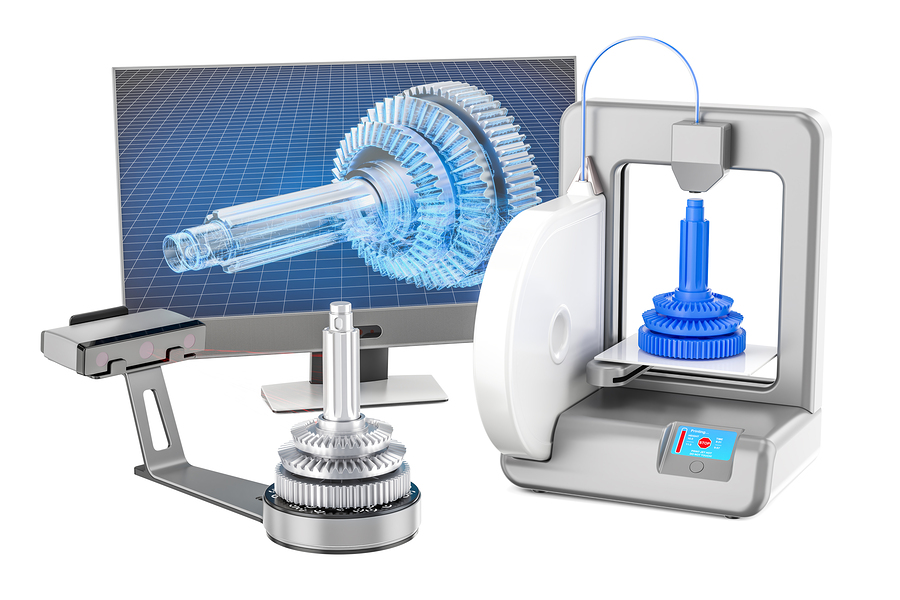

From aerospace designs to household products, 3D printing is making manufacturing more affordable, seamless, and reliable. 3D printing is the new wave in manufacturing with less waste, the ability to change designs as business needs change, and the added reliability of being able to consistently produce products. Manufacturing companies large and small are looking to the future and seeing that these are just a few of the benefits of investing in 3D printing. Further improvements come through the help of the new, innovative Jabil Additive Manufacturing Network.

Today, the Jabil Additive Manufacturing Network has 100 3D printers in operation in the United States, China, Singapore, Hungary, Mexico, and Spain. These industrial printers can sinter at high speeds and fabricate using fused filaments. In addition, they can print polymers and metals, making them sought-after machines for manufacturers. To further make production seamless for manufacturers, Jabil’s network addresses the problem of scaling 3D printing across networks with traceable manufacturing. Such ability is key for a business like HP that operates facilities in the United States and overseas. With Jabil’s network, HP can effortlessly shift printing jobs among different facilities.

Today, the Jabil Additive Manufacturing Network has 100 3D printers in operation in the United States, China, Singapore, Hungary, Mexico, and Spain. These industrial printers can sinter at high speeds and fabricate using fused filaments. In addition, they can print polymers and metals, making them sought-after machines for manufacturers. To further make production seamless for manufacturers, Jabil’s network addresses the problem of scaling 3D printing across networks with traceable manufacturing. Such ability is key for a business like HP that operates facilities in the United States and overseas. With Jabil’s network, HP can effortlessly shift printing jobs among different facilities.

HP is not alone in being a global company. Manufacturers have found that different parts of the world meet their business needs better than others, leading to them establishing multiple facilities all over the world. This is why distributed 3D printing is becoming an essential addition for many manufacturing businesses utilizing this technology. Until recently, it was an expensive venture to change any aspect of production across facilities. With Jabil’s distributed 3D printing network, all facilities are linked together, making it easy for global businesses to make changes without losing profits.

Increased productivity, integrated facilities, less waste, and the ability to change designs without the need to add new machines to the line is the future of manufacturing. A whole new world of possibilities is opening before the industry. 3D printing allows manufacturers to explore different ideas without costly changes and even collaborate on projects with other manufacturers utilizing the Jabil Additive Manufacturing Network to create new and innovative designs.

Technology and electronics are the present and the future. From Industrial Internet of Things-connected devices to industrial 3D printers, industries rely on electronics every day. This is why it is important they know who to contact when an electronic repair need arises.