Despite automation and globalization, manufacturing is not dead. In fact, it is alive and growing. With the boom of the Industrial Internet of Things (IIoT), we can expect great things in the future of manufacturing.

From internet-connected cellphones to wearable devices that track our fitness while streaming music, the IoT has significantly changed the way individuals go about their daily lives. It has even changed the way businesses collect information on current and potential customers and, as data collection gets more sophisticated, the Industrial IoT will continue to impact the landscape of the manufacturing industry.

How the Industrial IoT can improve equipment maintenance

Factories perform routine maintenance and checkups on the equipment that keeps them up and running. If just one piece is faulty, it impacts everyone. At best, it can cause defaults in the product or stop the line. At worst, it could put the lives of factory employees at risk.

Imagine a machine that talks to itself and other pieces of equipment daily, reporting on their status and needs. This information could drastically reduce production downtime while improving factory safety. Reports could also send highly detailed data, to help operators pinpoint the exact location of any malfunctions.

It not only has a positive impact on the entire factory but it also positively impacts the lives of each employee. For example, Caterpillar Inc. is already taking measures to integrate IIoT by investing and partnering with Uptake, an IoT company that uses fleet sensor data to create predictive analytics and diagnostics. This data helps find problems in fleets before they occur, which improves fleet availability and increases operational efficiency.

Will smart machines improve production?

For consumers today, cars can connect to the internet and exchange information with other connected devices. Autonomous vehicle manufacturers hope to use internet connectivity and smart technology to increase safety while simplifying the driving experience.

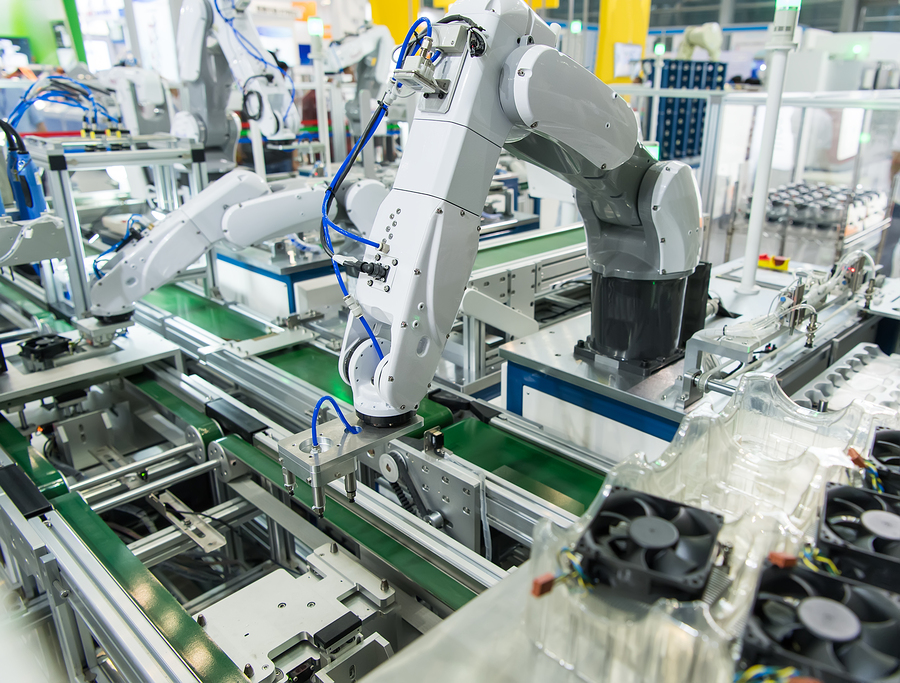

But consumers aren’t the only ones seeing IoT-driven changes. Industrial IoT in concert with smart machines can help address the growing complexity of customer demand. Smart machines can work with each other and the humans who run them to create more efficient manufacturing facilities. This includes:

- Using IoT sensors to create condition-based maintenance alerts or actively monitor the environment of the machine to ensure optimal conditions

- Monitoring production lines throughout the entire manufacturing process to better manage operational costs

- Tracking and sharing events with clients throughout the supply chain

- Creating more accurate inventories to help optimize supply and reduce shared costs

- Synthesizing manufacturing data and customer feedback to analyze and correct product quality issues

- Optimizing the manufacturing supply chain

All these capabilities of IIoT translate to improved production, higher efficiency, and better profit margins for manufacturers. Moreover, smart factories can learn and adapt to both increasing and decreasing consumer demand.