For decades, self-driving cars seemed like something out of a science fiction movie, until Tesla invented the first one. Aren’t you curious about the manufacturing process used to build it? Clearly, automotive manufacturing has come a long way over the years.

We’ve made major discoveries since the invention of the wheel. From horse-drawn carriages to self-driving cars, the way we travel has changed drastically. What hasn’t changed is the need for manufacturing. Despite humble beginnings, advancements in automotive manufacturing played a major role in many of the innovations we see in our travel today. Just how has this industry changed from then to now?

Automotive manufacturing: Then

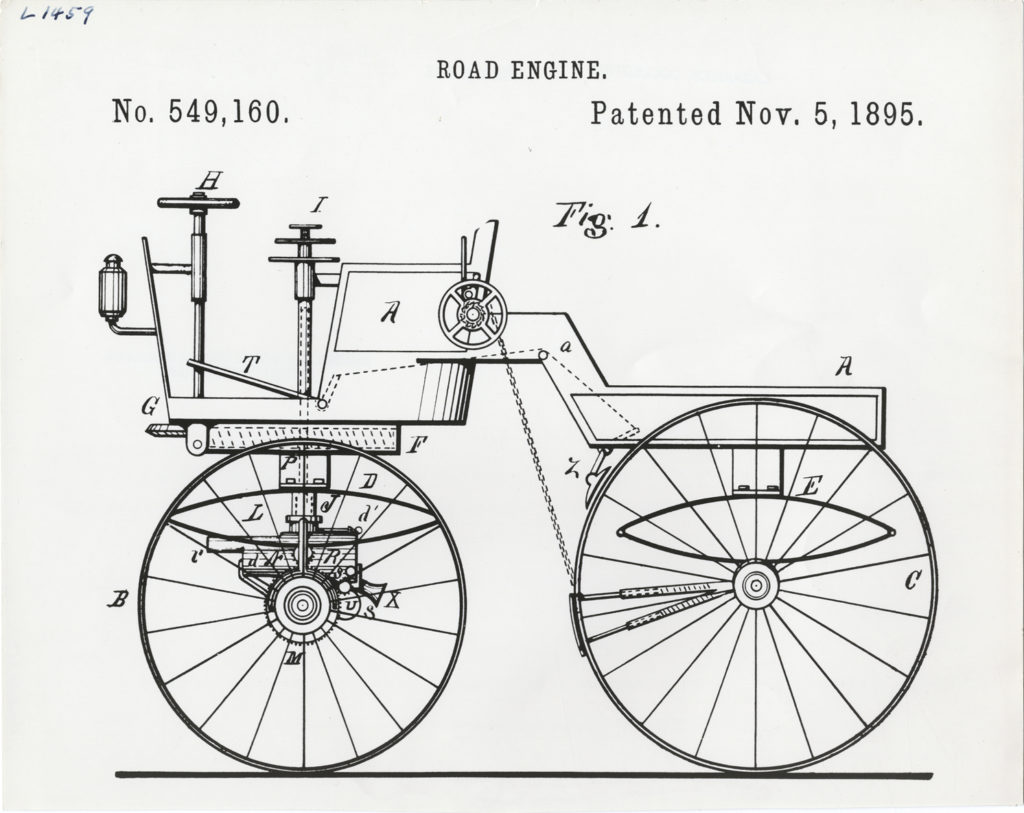

After the invention of the first cars in the 1800s, the great thinkers of the time saw a need for manufacturing locations and processes that would boost production. They needed a central location between the east coast and Chicago, and Detroit fit the description.

In the early part of the 20th century, Ransom Olds became the first to set up shop with his Oldsmobile. After that came Henry Ford with his Model T. It wasn’t long until Detroit became known as “Motor City,” with other major players following their lead. Both Chrysler and General Motors eventually built automotive manufacturing plants in Detroit as well.

The race to build automobiles wasn’t an easy one. Ironically enough, the first car bodies were delivered by horse-drawn carriages to the Ford factory. Another obstacle to production was the lack of assembly lines. Henry Ford became the first to address this issue.

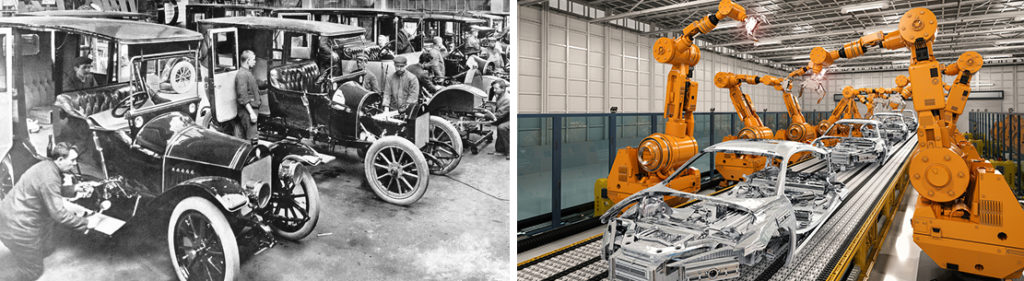

Parts of a vehicle were set up on sawhorses. Workers would move from station to station to piece the vehicle together. Even though this sped up production, it would be years before an automated assembly line would take production to the next level.

Automotive manufacturing: Now

Innovation throughout the years has brought major changes in automotive manufacturing. The most notable invention to increase production was the motorized assembly line. You can see how Ford was clearly thinking ahead, all he needed was a motorized line.

It wouldn’t be until the 1970s that robotic arms would come on the scene. These machines not only sped up production but also improved the safety of the work environment for many employees. With advancements in technology happening at breakneck speed, there’s no telling what we might witness in the future.

Materials used in automotive manufacturing through the years

Automobile manufacturing has seen a variety of materials used to build the cars we drive, beginning with the aluminum body of the Model T. Early on, Henry Ford switched to steel to lower cost of production. It wasn’t until the 1990s that manufacturers returned to aluminum. However, it only made up a small percentage of the actual material used in the car. In the last decade, there has been an increased use of aluminum, due to its light weight and durability.

Another material utilized by the industry in the past is sheet molding. This material consists of a reinforced fabric and resin. It was mostly used to build truck cabs and Corvette panels around 1970. The main draw of this material is its light weight and low costs.

From the late 20th century and through today, automotive manufacturers began and continue to use a platinum die cast for their vehicles. More recently, manufacturers built automobiles from numerous materials called multi-material composites. We have even witnessed the first 3D printed car.

Automotive manufacturing has seen huge changes since it began. As the manufacturing moves forward, we can expect even more advancements. Beginning with the first production facilities in Detroit, automotive manufacturers have always looked for better ways to construct new and exciting vehicles.