While troubleshooting, you have probably heard the term “relay” come up during your checks. Relays are one of the first things to be examined when a failure has occurred in an electrical cabinet. Why is this the case? It is simple – most relays have moving parts (except for solid state) to achieve electrical switching using a coil and a set of contacts and anything that moves mechanical is going to suffer an eventual failure. The term relay can describe a variety of components in your machine systems. Here we will go over a few of them and what causes them to fail.

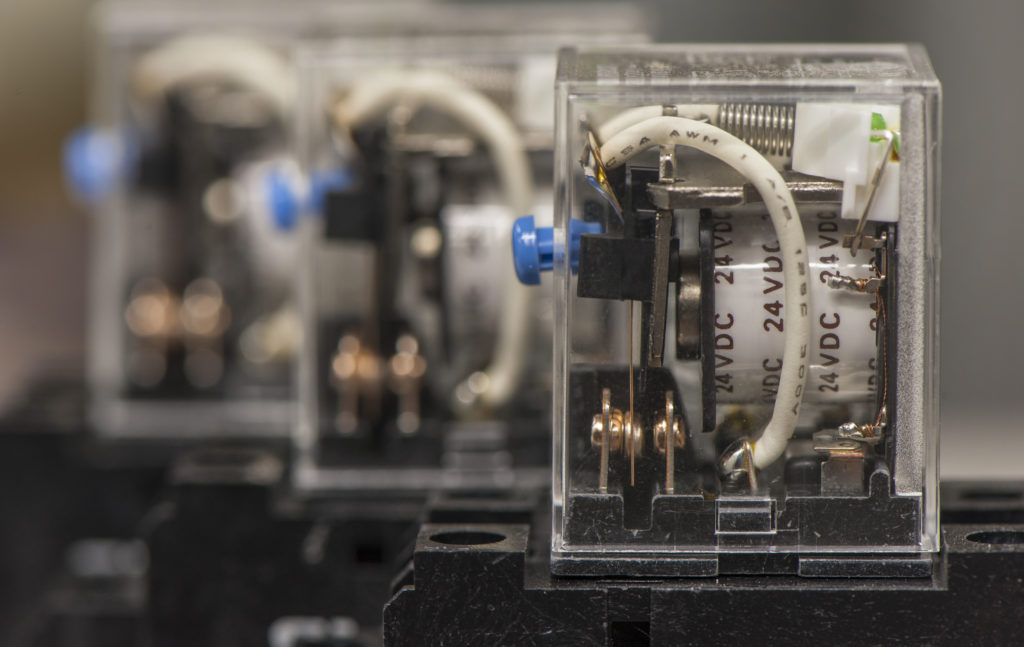

Electro-Mechanical Type Relays

These are one of the most common and oldest types of relays. Originally, they were invented for amplifying signals in telegraph systems. These days they are used mostly to provide switching in applications where using a small voltage to direct a relatively large amount of current is desired. There are many different kinds with endless varieties or internal structures, but the basic anatomy is a Coil, a Spring and a armature that closes and opens set of contacts. Most of the types of failures we see are involving the Contacts. If the mechanism is not making full contact or is stressed due to higher inrush current, carbon build up can happen due to excessive electrical arcing. Sometimes the relay will be designed in such a way that the cover can be removed, and the contacts cleaned, or in other cases a small voltage can be applied to “knock loose” the carbon build up. If these methods do not fix the issue likely the relay must be replaced.

Solid State Relays

This type of relay has not been around for very long, relatively speaking. The solid-state relay is usually much smaller than the mechanical type as it does not use a coil and mechanical mechanism to control its switching action. Instead a current is introduced to a internal sensor that triggers a semiconductor to perform the switching action. Solid state relays are considered to be somewhat more reliable than mechanical ones however they do still suffer the same age, heat and wear and tear failure modes that most electronic devices are subject to.

Contactors

A contactor is a larger more robustly built type of relay that is designed to withstand large currents. This type of relay is extensively used in motor control, sometimes as a stand-alone device and other times as a component of a larger motor control system. The main problem associated with contactors is excessive voltages and spikes that exceed the design. Other factors such as environmental damage from corrosion and heat, or mechanical issues such as vibration can contribute to their failure.

If you have a repair problem due to a relay that has failed, be sure to visit us online at www.gesrepair.com or call us at 1-877-249-1701 to learn more about our services. We’re proud to offer Surplus, Complete Repair and Maintenance on all types of Industrial Electronics, Servo Motors, AC and DC Motors, Hydraulics and Pneumatics. Please subscribe to our YouTube page and Like Us on Facebook! Thank you!