Guide to the DC Motor

Direct current (DC) motors initially came into use during the early 1800s. Developed by Hungarian engineer Ányos Jedlik, the instrument was soon adapted by physicist William Sturgeon and blacksmith Thomas Davenport, who made the first efforts to market the DC motor. However, the DC motor as it is known today was not developed until the 1870s when Belgian engineer Zénobe Gramme connected two dynamos to produce voltage.

The dominance of the DC motor in the industrial sector would last for little more than a decade before Nikola Tesla introduced the contemporary three-phase electrical system in 1888. Since that time, the DC motor has been eclipsed by the alternating current (AC) induction motor, yet many applications still use the DC motor.

Why We Still Use DC Motor

The continued popularity of the DC motor is largely due to its variable speed capabilities. The speed of a DC motor increases in proportion to the voltage it receives. Starting at zero, the voltage and speed rise together at corresponding levels.

By contrast, the induction motor runs at full speed at all times unless it is controlled with pulleys and belts. Induction motors can be speed-controlled with gearboxes and clutches. However, speed-control devices add to the complexity of such motors. As a consequence of such complexity, induction motors require more maintenance in more areas.

Advantages of DC Motors

A DC motor is capable of generating full torque in a range between zero and a base speed, which makes the DC ideal for cranes, lifts, elevators and conveyor belts. Applications such as these can be brought to instant stops as needed when the motor is running on full load. For the application to start back up, the motor must reassume full torque.

An elevator, for example, will be prompted to start and stop dozens and possibly hundreds of times throughout a given day. The motor that runs the elevator must be capable of instantly running at full capacity when the open/close and floor buttons are pressed. That same motor must also be able to stop the application when a floor is reached. The demands at play here are different than an automobile, where time is required to either rev an engine or slow down the vehicle.

The operating range of a DC motor is split into three different regions:

- The First Region: Alternately referred to as the constant-torque range and labeled variable power/constant torque (VP/CT), this region is from zero to base speed.

- The Second Region: Alternately referred to as the field-weakening (FW) range and labeled constant power/variable torque (CP/VT), this region is where the motor operates between base speed and anywhere from two to three times that speed.

- The Third Region: Alternately referred to as the variable power/variable torque (VP/VT) region, this region builds upon FW and operates at four to five times the base speed.

The two main benefits of DC motors are the speed variation and torque. With a DC motor, a variation in speed or torque can be accomplished in two different ways. One is to change the armature voltage. Another option is to change the field voltage. Alternately, both methods can be combined to achieve speed variation.

- Armature Voltage Control: With fixed-field excitation and armature voltage control, a DC motor will develop torque independent of the speed. Uses of this nature are referred to as constant torque operation.

- Shunt Field Control: The number of turns in the shunt windings means a strong magnetic field can be generated, but this field meets a higher resistance because of the small gauge of the winding wires. Which means the shunt coil has less current flowing through it and a lower starting torque.

Armature voltage and shunt field control can be combined for a broader range of speed. For speeds under the base speed with steady torque, armature voltage is employed. For speeds faster than the base speed with steady horsepower, shunt field control is employed.

Torque

An electric motor is designed to make mechanical energy out of electrical energy. The force that causes rotation on a shaft, also known as torque, is the very essence of a motor’s operation. The main reason why DC motors are used today is due to their constant torque, which is useful for numerous types of processes of varying speed.

When a DC motor is used, the power supply is a crucial factor. DC voltage is applied to a motor by an electronic drive, which offers a pulse waveform akin to the voltage of a battery. Pulse waveforms are distinguished by form factors and designated by letter codes — A, C, D, E and K — established by the National Electrical Manufacturers’ Association (NEMA).

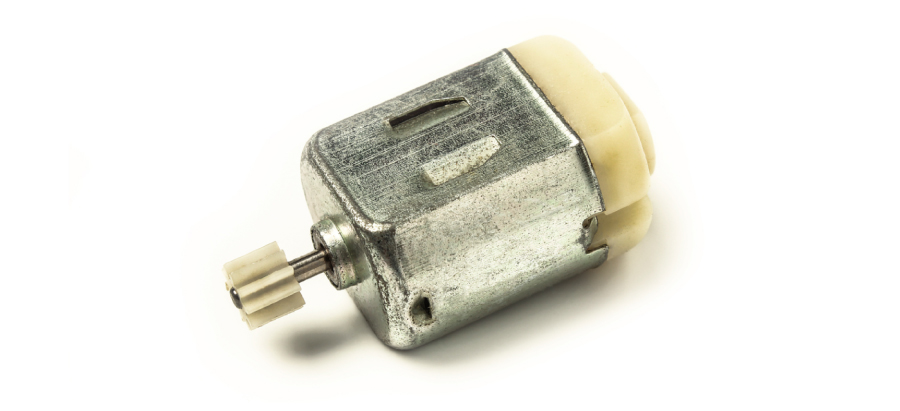

Types of DC Motors

DC motors are produced in four types — shunt motors, series motors, compound wound/stabilized shunt motors and permanent magnet motors. When any one of the four DC motor types is used in an industrial process, considerations must be made for variations in speed and torque of each load.

- Shunt Motors

A shunt motor will either have separate or parallel armature and field supplies. Either way, shunt motors offer between 5 and 10 percent speed regulation and are quickly able to yield 300 times the full-load torque.

- Series Motors

With series-circuit-connected field and armature, series motors are used for applications that demand high torque, including crane and locomotive operations. With a 500 percent full-load starting torque, a load increase results in a simultaneous field and armature current. Compared to a shunt motor, a series motor is capable of greater increases in torque. However, the speed regulation of a shunt motor is better than that of a series motor. Without the mechanical load, the series motor would go faster and faster with no regulation. Consequently, the motor would be destroyed by the force of the armature.

- Compound Wound Motors

In applications that require speed regulations that neither a series motor or shunt motor can provide, compound wound motors are the alternative. When under load, a compound wound motor is capable of consistent speed and high starting torque. This performance quality is due to the balance of the armature and field circuits. The motor’s torque output is increased by corresponding increases in the field flux, which are triggered by currents of an applied load. Compared to a shunt motor, a compound wound motor is capable of better speed reduction due to the increased field flux.

- Permanent Magnet Motors

In applications where response time is of utmost importance, permanent magnet motors are the preferred alternative to shunt and series motors. Nonetheless, shunt motors and permanent magnet motors have similar qualities in terms of speed. Designed with regular armatures, the magnets in this motor type are located in the field section, not the windings. Because they don’t need field supply, permanent magnet motors cost less to use in industrial applications. However, the magnetism and torque of a permanent magnet motor decline with the passing of time. To re-magnetize a permanent magnet motor, some are constructed with built-in windings.

DC Motor Issues

If used in an unsafe enclosure, the non-insulated parts of a DC motor are liable to fail prematurely. The parts vulnerable to electrical failure include the connections, commutator and rigging. The types of contaminants that work as conductors in a DC motor include acid salt, carbon and other elements both wet and dry.

At low voltage, current can be conducted for several inches by wet contaminants. Gradually, the air-bound oily mist of a working environment will settle onto the surfaces of a DC motor. As the surfaces become stickier due to contaminant buildup, currents become shorted or grounded. This process can go on for some years with no noticeable effects on the performance of a machine. However, if the leakage becomes too intense, the failure of a given machine is almost inevitable.

- Overload

One of the biggest causes of over-temperature in a DC motor is overload, but this is far from the only potential cause. The operating temperature of a machine can also be affected by the ambient temperatures in the surrounding working environment. For example, if the conditions in a factory are far too hot, the machine itself is liable to go over temperature. Another big cause of DC motor over-temperature is dirty filters. If the filters on a machine become clogged, the machine cannot ventilate properly. Consequently, the machine is liable to store excess heat that could ultimately wear down the working components.

When operation temperatures soar, differential expansion causes cracks in the insulation. This exposes the circuit to contamination, which gradually leads to machine failure. The hardening and shrinking of insulation lead to a loss of strength in such material. Humid external temperatures can also have a damaging effect on the grease of internal moving parts, which leads to friction, acidic buildup and corrosion along touching metal surfaces. Exterior temperatures more than 40 degrees Celsius can also have a damaging impact on cables and brushes.

- Contamination

Contaminants of a nonconducting nature can also lead to over-temperature in a DC motor. Byproducts from factory processes, such as dust and sand, are some of the primary contaminants in this regard. Contaminating elements can also wear away at the varnish and insulation of machine components.

Aside from over-temperature, one of the more dangerous effects of metal dust is how it can serve as a conducting path for leakage currents, be they of the shorting or grounding type. This can occur when the contaminant makes contact with the electrical circuit. Other contaminants that have a similar conducting effect include carbon, carborundum and salt. An insulated circuit is liable to develop openings in odd spots if trapped air expands or inflicts rotational stress due to pressure within the insulation system.

- Oil Deposits

Performance issues can also arise early in the service life of a DC motor if oily residue adheres to the surface of internal parts. Regardless of whether the parts are insulated, oily deposits can cause contaminants to stick and have damaging effects on machinery. Insulation can also be damaged by contact with water, which can disperse along the surface of internal components due to condensation. A non-conducting contaminant can easily become a conductor for leakage current. Sorting and grounding currents are generated by paths created by leakage deposits, which are caused by internal moisture. Over-heat is one of the primary causes of the condensation that leads to these effects.

- Vibration

Vibrations of a high intensity can also have a damaging effect on a DC motor. Intense vibrations cause stress along the shaft and this can lead to shorts between the turns and layers of conductors. An electric circuit can also become exposed to contamination due to high vibration because of cracks along the insulation that result from stress. Vibration can also harden the conductor and lead to cracking, hence an open circuit. If brush bouncing occurs, the vibrations could lead to commutation issues. If the problem of intense vibration continues unchecked, stress between the metals could result in hastened wear of the bearings and castings.

- Altitude

A motor is rated according to its ability to operate at any height of up to 1,000 meters, or 3,300 feet, up to which the altitude is considered equal to ground-level in terms of performance expectations. At altitudes beyond 3,300 feet, a de-rating is required to account for the loss of air density at such heights. For every 1,000 feet that a DC motor might be used beyond the altitude of 3,300 feet, it is de-rated by 3 percent to account for the additional cooling needed due to reduced air. Depending on the design of the motor, a blower or a larger motor will be required for sufficient coolness.

- Ambient Temperature

In environments with excess humidity, a motor needs to be equipped to operate within the high-temperature surroundings. Motors specifically designed for these environments have lower winding temperature rise. The lubricant also needs to be taken into account for any motor used in a work setting that exceeds 50 degrees Celcius. If the internal parts get too hot, the lubricant is liable to lose its viscosity and effectiveness. When this happens, friction occurs between the surfaces of moving metal components and the motor overheats. Though a DC motor can be used in ambient temperatures above 50 degrees Celcius, special steps, as laid out in an operator’s manual, should be taken beforehand.

Generally, the easiest way to de-rate a motor for humid ambient temperatures is to adjust the rating of the horsepower and to use the motor at field weakening. This will allow for lower-current operation for the field and armature. If the ambient temperature is below 40 degrees Celcius, a regular machine is generally selected for use at a regular load. If temperatures are kept below this level, a standard DC motor can be employed at overload as long as the ambient remains low, the commutation and shaft stresses are green-lighted by the factory and overload protection is available in case it becomes necessary.

DC Motor Services and Repairs From Global Electronic Services

For B2B applications throughout the industrial sector, it is crucial to have DC motors that operate at full capacity for all applicable processes. For more than 60,000 of the world’s leading manufacturers and distributors, Global Electronic Services offers your company repair and service work on a full range of DC and AC motors, in addition to hydraulics, pneumatics, electronics and servo motors. Subscribe to our blog and call or contact us today for more information.