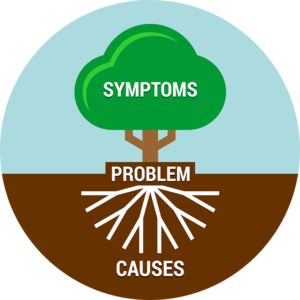

Solving a problem means understanding its root cause. Until you’re addressing the root of the problem directly, you’re only attacking symptoms. This is a fundamental tenet of industrial maintenance and a core philosophy of any good maintenance approach.

But how exactly do you get to the root of the problem? Moreover, how do you distinguish the core a problem from one of its many symptoms?

A root cause analysis is the most direct approach to determine the central catalyst for a problem. However, there is no one-size-fits-all approach to root cause analysis. Repair technicians must choose the appropriate analytical method for their unique approach.

How to approach root cause analysis

The core concept of root cause analysis is simple: Weed out the symptoms until you pinpoint the cause or causes of component failure. Regardless of how you approach it, root cause analysis needs to be structured and methodical. To that end, there are several recognized approaches to root cause analysis. Here are five of the most popular:

1. Causal factor tree — A robust approach to root cause analysis, the causal factor tree modality is extremely visual. It starts with identifying the problem and writing it down, with each potential cause branching from the problem. Catalysts are then added to each causal branch until the nature of the core problem is identified. This is a popular approach because it forces methodical dissection of the problem.

2. Failure Modes and Effects Analysis (FMEA) — The most comprehensive approach to root cause analysis and the most frequently used, the FMEA process uses hypothetical “what if?” questions to stimulate an understanding of the problem. It’s used to establish cause and effect relationships that explain why certain problems occur — namely, the problem you’re currently dealing with.

2. Failure Modes and Effects Analysis (FMEA) — The most comprehensive approach to root cause analysis and the most frequently used, the FMEA process uses hypothetical “what if?” questions to stimulate an understanding of the problem. It’s used to establish cause and effect relationships that explain why certain problems occur — namely, the problem you’re currently dealing with.

3. Change analysis — The central question in change analysis is “What’s different about this machine as opposed to a working one?”. Figuring out what’s different will shed light on how a problem arose, allowing maintenance professionals to resolve core issues. Change analysis is simple; however, it means having a benchmark to compare failures to, which isn’t always feasible.

4. Five Whys — Perhaps the simplest approach to root cause analysis, the Five Whys methodology is just one step, repeated over and over again! All you need to do is ask, “Why?” Eventually, the answer to your question will lead you back to the root of the problems you’re inquiring about. The Five part of this approach stems from the belief that you can complete a root cause analysis in five steps or fewer.

5. Data analytics — In the age of readily available data, combing through aggregated information can shed light on catalysts for major problems. Seeing a spike in a specific data set may signal the root cause of a malfunction down the line. Best of all, data can yield insight without invasive inspections or time-consuming troubleshooting.

There are even more approaches beyond these five, giving maintenance professionals a veritable toolbox of options as they seek to understand what’s causing equipment failures.

Get to the root of the problem

When dealing with industrial maintenance, your first priority should always be to get to the bottom of the problem. No matter how you get there, the result of your root cause analysis will yield better maintenance results and more effective solutions for your machinery.