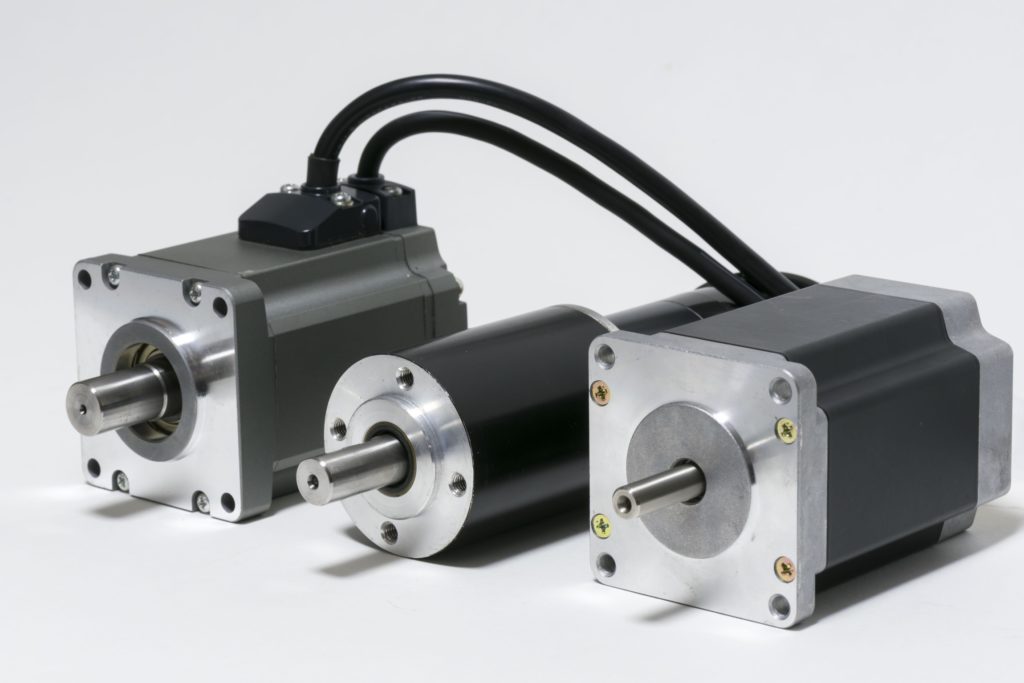

What is a servo motor used for? Servo motors — DC motors that allow precise controlling of angular positions — are miraculous devices that are used quite frequently in manufacturing. You can find servo motor applications just about everywhere, from the conveyor belts that move product up and down the assembly line to the robotic arms that help make those products as their parts move from station to station.

Coming up with new ways for using a servo motor can be an art in itself, and though there are plenty of servo motor uses you’re probably well aware of, you may not have considered a number of them. Here are some of the less common servo motor uses you may want to think about:

- Cameras: Have you ever wondered how a modern camera focuses its images? Often, the answer is with a tiny, very precise servo motor that corrects the lens as necessary to sharpen images until they’re in focus.

- Metalworking: When most people think of metalworking, they may think of diecasts, lathes and other cutting, shaping and melting machines. However, servo motors can be an extremely important element in many of these machines, providing the precise control necessary to fabricate certain items, such as those used in the aerospace or automotive industries.

- Woodworking: By the same token, mass production of specific wood shapes, like various furniture items, can be greatly accelerated without losing precision through the application of machines using servo motors.

- Solar array and antenna positioning: Servo motors are the perfect mechanism for moving solar panels into place and allowing them to keep following the sun or rotating antennae to make sure they’re getting the best signal reception possible.

- Rocket ships: Any number of processes in aerospace may owe their functioning to the precise positioning and rotation enabled by servo motors.

- Robot pets: It’s true. Roboticists have made great strides in building robotic dogs and cats that use servo motors to get around extremely effectively without falling over (and with the ability to get back up when they do). You wouldn’t mistake one for your own beloved Fido or Puss ‘n’ Boots, but it’s pretty incredible what these pets can do with a few servo motors helping them along.

- Textiles: Just as with metal and woodworking, servo motors are not the first thing that comes to mind when people think of textile production. But of course, like most of today’s major industries, the textile industry has moved far beyond a bunch of workers sitting in rows weaving. The textile industry uses complex weaving, knitting and spinning machines to make today’s fabrics and the blankets, drapes and articles of clothing that come from them, and servo motors are a crucial element in making those machines run properly.

- Automatic doors: You didn’t think those doors that open as soon as you approach them at the grocery store or the airport do it by magic, did you? The action of pulling the doors open and closed can be attributed to servo motors inside the door. They’re connected to sensors that let them know when to jump into action.

- Remote control toys: Certain modern toys are another great application for servo motors. Many of today’s motorized toy cars, planes and even tiny robots have servo motors in them that allow children to control them.

- Printing presses: When someone is printing a newspaper, magazine or other mass-printed item, it’s essential for them to be able to move the printing head to precise locations on the page to make sure the print appears in the layout precisely as planned. Servo motors allow printers to make sure this process goes smoothly and everything ends up in its proper place.

Servo Motors for Your Business

What types of servo motor applications do you use in your manufacturing business? Whether your servo motors are used for common applications, rarer ones or a combination of both, it’s crucial that those servo motors be functioning at top capacity and without errors at all times so that everyone in your company can keep working without any holdups.

If any of your servo motors are down, you need a company that can take it apart and give you an estimate on repair. Then, you should receive a fully functioning motor quickly so that your operations can be back on track in a matter of days, reducing your downtime.

When you need help with servo motor repair, you can contact General Electronic Services for a free estimate.