Machine stress manifests in many different ways. Some problems are more distinct than others. Friction, for example, can be seen, heard, or even smelled! Other problems such as soft foot offer only subtle clues they’re occurring. In fact, a condition such as soft foot requires specific checking to make sure it’s not going unnoticed. It’s a sneaky condition with problematic ends.

What is soft foot?

Soft foot affects the stability of machinery. Essentially, it’s when equipment is off balance — like a restaurant table that shifts ever so slightly when someone rests their hands on it. But, unlike that restaurant table, fixing soft foot isn’t as easy as putting a coaster under one of the table legs to even it out!

Several things can cause soft foot to develop. Among the most common are dirt and debris buildups under footing, resulting in a slight imbalance. Small damages such as dents or warped sections of machinery can also result in soft foot. Finally, base bolts that are too loose or too tight can affect balance.

Soft foot is very hard to spot in a factory setting. Any machine that’s openly wobbly will get the attention it needs. Soft foot issues generally pertain to imbalances that are millimeters (even micrometers) off-kilter. The equipment won’t visibly move, and you won’t be able to feel any sort of shift. But at a granular level, there’s excess motion.

Testing for soft foot

Because it’s so hard to spot outright, soft foot needs to be tested for. Generally, equipment with recurring wear issues is a good candidate. The process for testing is simple:

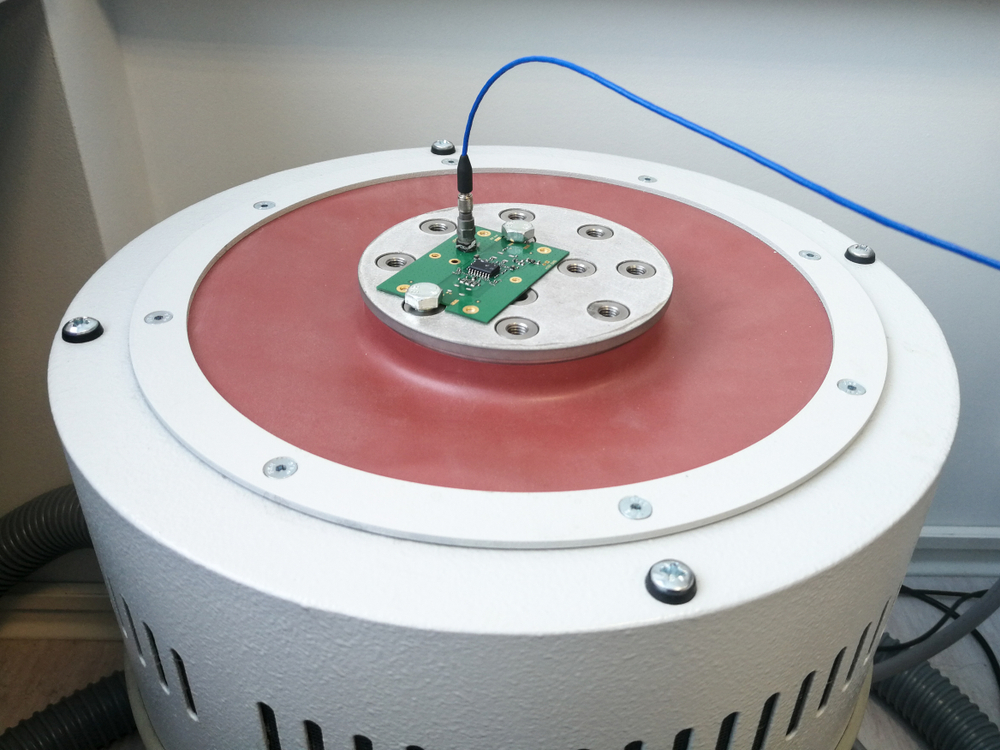

- Mount an accelerometer on machinery with a suspected soft foot issue;

- Monitor rotation speed vibration (1x), recognizing the desired peak;

- While monitoring, loosen the mounting bolt slightly.

If the vibration reduces noticeably in amplitude after loosening the bolt, soft foot is present. The accelerometer will show quantifiable proof of an imbalance, with the loosening of the mounting bolt proving the source of the excess vibration.

When soft foot goes unchecked

The real issue with soft foot isn’t the imbalance — it’s the problems resulting from it. Particularly for machinery with rotating parts, it doesn’t take long for the excessive vibration caused by soft foot to escalate. Unbalanced footing amplifies the vibration of everyday operation, exacerbating wear and tear. Misalignment, component fatigue, excessive power consumption, and equipment distortion are all close to follow.

Correcting soft foot

Despite its difficulty to spot, solving soft foot is a relatively simple affair. Re-bolting mounting flanges and anchors to appropriate specifications can solve this problem if detected early. Shims may also work temporarily. If stress warping or other vibration-related issues have taken root, they may need metalworking or part replacements to re-establish footing.

After correction, a technician should recalibrate the entire piece of machinery, measuring vibration during operation to ensure safe levels. Soft foot issues can persist or get worse if the first solution isn’t a measured one!