There’s a lot to love about additive manufacturing. It has the power to lower costs, streamline repeatable processes, and take human intervention out of the equation. But as we all know by now, additive manufacturing also comes with a few barriers to implementation. This technology has never really reached its peak potential. That said, new possibilities are on the horizon as more and more manufacturers figure out additive manufacturing’s role within operations.

Additive manufacturing today

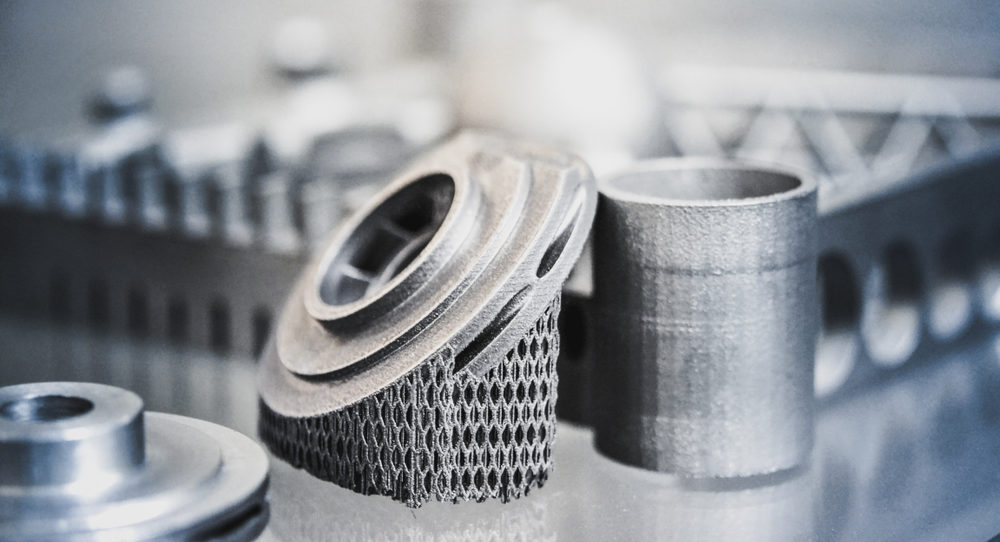

Today’s additive manufacturing landscape is very different from the past. While 3D printing has become central in some industries — running peripheral to injection molding and the like — new manufacturing sectors are picking up on its capabilities: most notably, aerospace. Companies such as Airbus, Boeing, and others have made additive manufacturing part of their core manufacturing strategy.

Also dabbling in additive manufacturing today are automotive companies. From luxury manufacturers such as Bugatti, to everyman manufacturers such as Ford, additive manufacturing may prove key to unlocking value in the manufacturing process. Today’s 3D printed brake calipers may be tomorrow’s 3D printed unibodies!

It all comes down to cost and convenience. As many manufacturers are finding, the cost of additive manufacturing could be drastically lower than traditional assembly over time. The first and biggest barrier is the cost of bringing additive manufacturing technologies to the factory floor.

The trajectory of additive manufacturing

Because of its parallels to injection molding and the rapid prototyping capabilities it offers, additive manufacturing may soon become a staple in the health care field. Specifically, additive manufacturing for medical devices may not be far off.

Like other industries, health care’s foray into additive manufacturing will start small. For example, 3D printed braces and custom-molded assistive devices are already making inroads, delivering quality of life improvements to those using them. From there, the possibilities are boundless. As an early-stage example, Massachusetts-based company Biomodex is experimenting with patient-specific 3D printing that can create lifelike prosthetics based on CT scans.

Not far behind health care, additive manufacturing for construction is picking up steam. Several companies have already printed entire homes! And while printing an entire home is largely a display of capability, the focus on additive manufacturing for prefab construction materials is a very real possibility with growing demand. The result is sure to be quality construction materials at a fraction of the cost.

New possibilities, same old barriers

Renewed interest in additive manufacturing has brought classic problems back into the spotlight. For every potentially great application, there’s a barrier standing in front of it. Most often this barrier is cost. Equipment has come down in price, but not to a level accessible for full-scale manufacturing. Companies must instead invest tens of millions of dollars to even test additive manufacturing, not counting the training and hiring costs that come with any new tech.

Another issue growing more prevalent with modern adoption of 3D printing is regulatory concerns. Can an additive manufacturing machine live up to the various compliance benchmarks across different manufacturing sectors? The United States Food and Drug Administration (FDA) has issued compliance standards for additive manufacturing that are stringent and precise. Other oversight bureaus have yet to do the same. When they do, it could pose problems for early adopters who need to raise their own standards.

The bright spot among these known barriers to adoption is the increased prevalence of success stories around additive manufacturing. If it can work successfully in the aerospace industry, why not others? Many manufacturers will soon put this reasoning to the test.