Condition-based monitoring is the new gold standard in maintaining equipment. Machines receive service before they break down, and techs respond to anomalies in real time — all but guaranteeing the avoidance of unpredicted downtime. And while no system is perfect, condition-based monitoring sets the tone for smooth, scheduled, predictable factory maintenance and repair. Unfortunately, many manufacturers still have yet to make a full transition to this system.

Barriers do exist …

There are barriers to a condition-based monitoring system. Smart equipment sensors are the cornerstone of real-time monitoring, and they don’t often come cheap. Similarly, there’s a learning curve for condition-based monitoring that goes well beyond just responding to system triggers. Maintenance techs need training to spot trends and understand the data provided by sensors.

… but the barriers are worth surmounting

Despite obstacles to implementation, it’s easier to transition to condition-based monitoring than most manufacturers realize. And the urgency of this efficient maintenance approach demands more consideration than ever before. Take a look at the following reasons to make a concerted effort to implement condition-based monitoring this year:

1. Less manpower required. The more unscheduled, unanticipated maintenance you have to perform, the more manpower you need to dedicate to keeping your operations running smoothly.

2. Saved costs. Yes, there’s an upfront investment in condition-based monitoring technologies. But this cost is easily and quickly recouped by avoiding just one major shutdown event that might’ve otherwise occurred.

3. Better equipment life. Letting a machine run to failure or beyond appropriate service dates will shave valuable service years off its life. Addressing problems as they arise keeps unnecessary wear out of the equation, adding those years back on.

3. Better equipment life. Letting a machine run to failure or beyond appropriate service dates will shave valuable service years off its life. Addressing problems as they arise keeps unnecessary wear out of the equation, adding those years back on.

4. Better understanding of equipment. Getting familiar with the real-time condition of equipment sheds light on its true maintenance needs. Beyond manufacturer specifications or best practices, you’ll see exactly what your equipment needs.

5. Better understanding of conditions. More than knowing your equipment, condition-based monitoring sheds light on how it’s being affected and by what variables. From vibration to temperature, data is present for dissection, leading to improved maintenance.

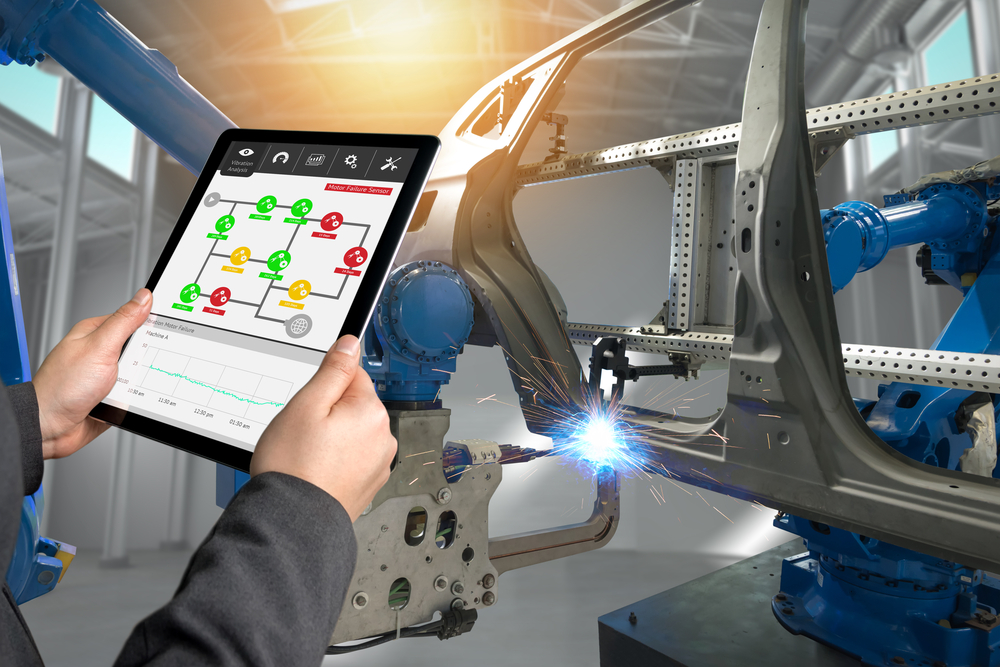

6. Remote monitoring. Modern condition monitoring systems are part of a network, meaning they’re accessible remotely. For factories entering the new age of connected tech, condition-based monitoring is the ideal starting point, providing high ROI.

7. Folds into the IIoT. Smart sensors are the simplest way to introduce your factory to the industrial internet of things (IIoT). Building this ecosystem and expanding it is the perfect foray into the world of bigger, more invested IIoT systems.

8. Early-warning potential. The prime reason for condition-based monitoring? Real-time insights. See variables change and respond to them instantly, before a situation goes critical and peripheral troubles occur.

All these benefits bind together to create undeniable value for manufacturers. In an age where maintenance, repair, and operations (MRO) are central to efficiency and cost savings, condition-based monitoring offers unparalleled potential.

Put condition-based monitoring into practice

This is the year to bite the bullet and make the investment in condition-based monitoring. And, just as important, factories need to make the investment in a management system that supports this MRO approach. This includes training techs, delegating responsibilities, setting expectations, championing predictive maintenance, and developing standard operating procedures (SOPs).

Condition-based monitoring is the cornerstone in a continuum of preventive maintenance. Instead of reacting, ensure your factory is anticipating based on a robust stream of data and information about your equipment.