Smartphones are ubiquitous. Not only are they in the pocket or purse of more than 2.5 billion people, they’re also quickly becoming part of everyday jobs. This includes traditional trade jobs, such as factory maintenance. In factories especially, mobile technologies have unlocked a wealth of opportunities across operations. But it’s arguable that none have benefitted more from mobile technology than maintenance and repair techs.

Of all the different areas of factory operation, few are as data-driven (or data-demanding) as repair and maintenance. Mobile technology and cloud computing have introduced a new age of efficiency and effectiveness for repair, maintenance, and operations (MRO).

The clear focus on mobile tech

The reasons behind mobile tech’s rise to prominence in factories are numerous. These benefits — which include flexibility, integration, cloud computing, data accessibility, and more — are clear in the focus of executives:

- In a survey of industrial manufacturing CEOs, 73% cited mobile technologies as being important to strategic growth.

- More than 50% of executives see the potential for real-time communication between workers and machines, including mobile as the path to achieving it.

- Manufacturers incorporating mobile into their operations saw an average of 42 minutes of saved time per employee each day, as well as a 75% increase in worker availability.

The most telling statistic about the rise of mobile is this one: 80% of manufacturing companies developed mobile apps since 2013. It’s clear that mobile has entrenched itself into manufacturing.

Putting mobile to work

The applications for mobile technology are tremendous. For MRO alone, smartphones and tablets have enabled efficiency, productivity, and oversight in ways like never before:

- Automation of parts inventories is taking the manual labor out of maintaining stock parts. Not only is this reducing the manpower required to effectively manage inventories, it’s also reducing costly errors within the part tracking and ordering processes.

- Machine-level compliance tracking is simple and provides a fundamental gateway for preventive maintenance plans. Real-time machine monitoring enables real-time repair and maintenance responses.

- Field service becomes instantly easier with a robust knowledge base in the palm of your hand. Field techs using smartphones and tablets have access to all the information they need to facilitate proper repairs and maintenance.

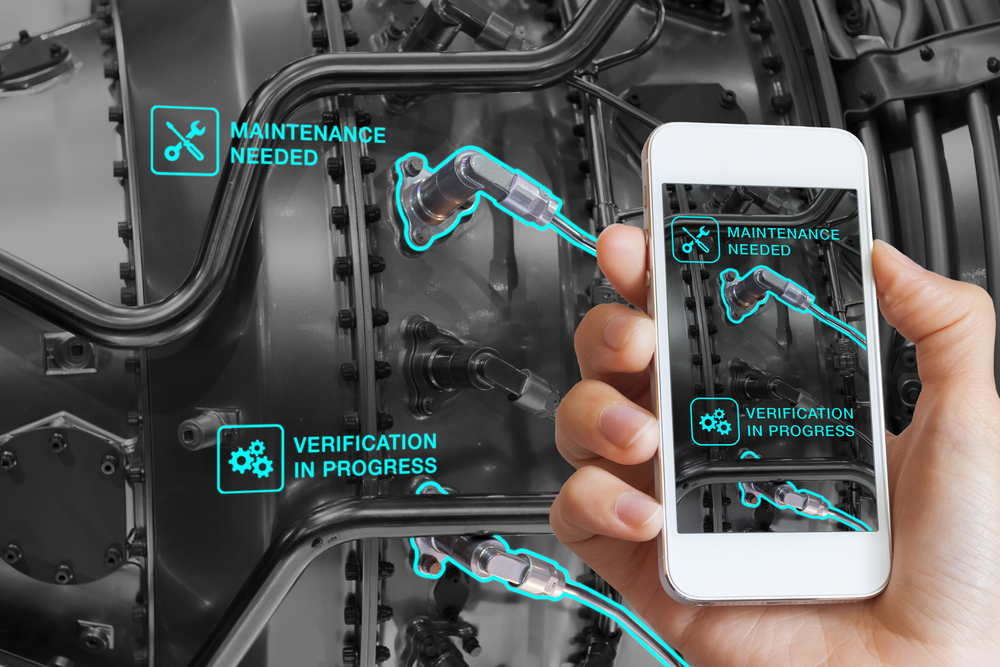

- The multimedia capabilities of mobile tech bring a robust set of tools to the factory floor. Techs can use augmented reality (AR) and virtual reality (VR) to troubleshoot, watch videos to quickly learn, take photos and record video for evidence catalogs, and much more — all from a single device.

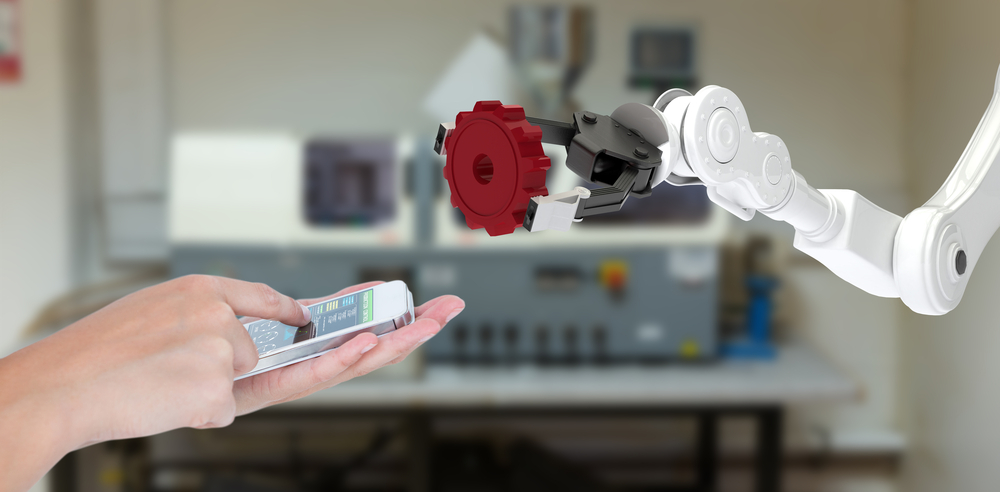

These are only a few of the numerous applications mobile technology has to offer. By itself, mobile’s opportunities are plentiful; when paired with the ever-growing industrial internet of things (IIoT), they’re practically infinite.

Anchoring the IIoT

The IIoT is inescapable at this point. Early adopters have operated within a smart ecosystem for years. Now, as the remainder of manufacturers adopt smarter tech to remain competitive, mobile serves as a smart entryway into the IIoT and an anchor for managing it.

With about 8.4 billion devices expected to make up the IIoT this year, communication between them and operation of each device demands a cloud connection. And because mobile tech is a physical manifestation of the benefits of the cloud, it has quickly become the tether linking the IIoT.

Today, techs pair IIoT sensors with tablets to instantly aggregate data while using smartphones to access inventory data from an off-site location. Every tap of the screen powers the IIoT ecosystem. With AR continuing to roll out new opportunities, HMIs unlocking better insights, and assistive robots growing in utility, mobile will remain central to a smarter, more efficient factory.