Industry 4.0 and the industrial internet of things (IIoT) are more than just buzzwords. The reality of these highly touted terms is a culmination of technologies that are quickly redefining the way we look at manufacturing. Instead of putting noses to grindstones, today’s factory workers are putting fingers to tablets and utilizing a slew of technologies to do better, faster work, with fewer errors. Here’s what Industry 4.0 and the IIoT are all about:

1. Artificial intelligence (AI) — The ability for programs and algorithms to provide insights on-par with or beyond human capability is one of the biggest features of the IIoT. AI powers these insights. Machine learning and predictive analysis are making inroads into areas such as maintenance, supply chain management, and quality assurance, among others.

2. Augmented reality (AR) — Making the intangibles of data into visual, manipulatable concepts is the premise of AR. AR allows repair techs to see parts and systems from all angles, in real time, so they can make manipulations and adjustments with acuity. Moreover, manufacturers use AR to plan, proportion, and position factors within the facility environment in a more purposeful way.

3. Big data — Data powers the IIoT and is the most important drive of Industry 4.0. It’s now possible to capture data on just about any process or procedure to learn more about the fundamentals of what works versus what doesn’t. Data powers decision-making across the factory floor and helps executives identify opportunities for improvement wherever they might exist.

4. Sensors and beacons — Data may be king in Industry 4.0, but to capture it, manufacturers need sensor and beacon integration. These devices are at the forefront of technologies such as predictive technology, fail-safe mechanisms, alerting and responding protocols, and more. They’re the key factors for integration and the devices responsible for translating physical manufacturing concepts into digital data points.

5. The cloud — Autonomy and accessibility are the core tenets of cloud computing, paving the way for factories to work smarter, not harder. Cloud computing enables shared data, system integration, and facilities oversight in a more comprehensive way, with better control. Most of all, cloud computing is breaking down the physical barriers holding back the global economy.

6. Cybersecurity — With more devices connected to the internet and more data stored in the cloud, cybersecurity has emerged as a chief tenet of the IIoT. As users discern the value of data, its protections are becoming more robust. This is also paving the way for more trust in the IIoT and affiliated technologies, pushing more innovation in the tech sector and better innovation on the manufacturing floor.

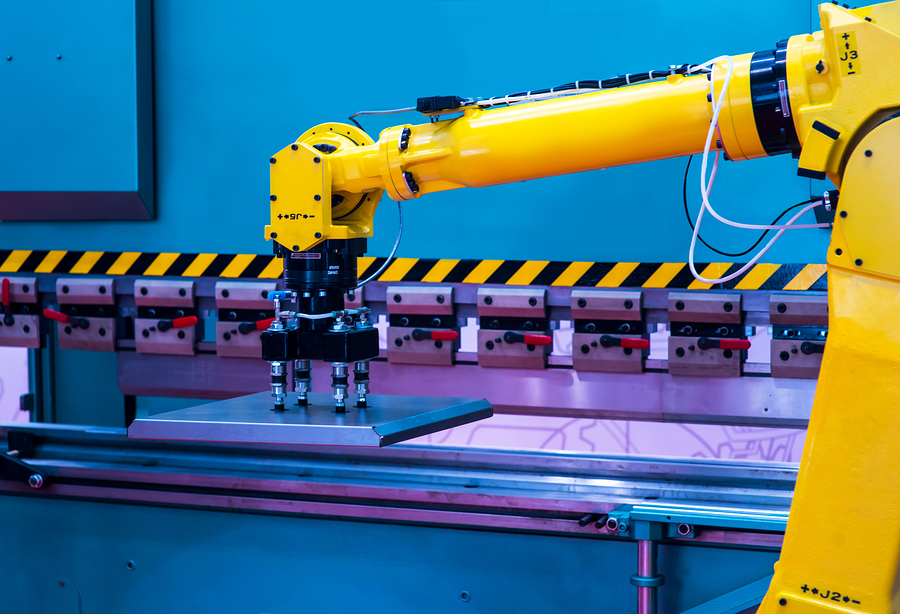

7. Robotics — Robotics is by no means new to the world of manufacturing, but it’s taking on a significance not seen before. Robots is powering everything from human-machine interfaces to sensor networks powering maintenance automations. Robotics emerged during Industry 3.0 and will likely continue to serve as a cornerstone of Industry 4.0.

These pillars of the IIoT are what will likely shape manufacturing throughout the current evolution of the industry. Each plays a pivotal role in how the new technologies will likely form and grow, and each will open the door for even more innovation in the future.