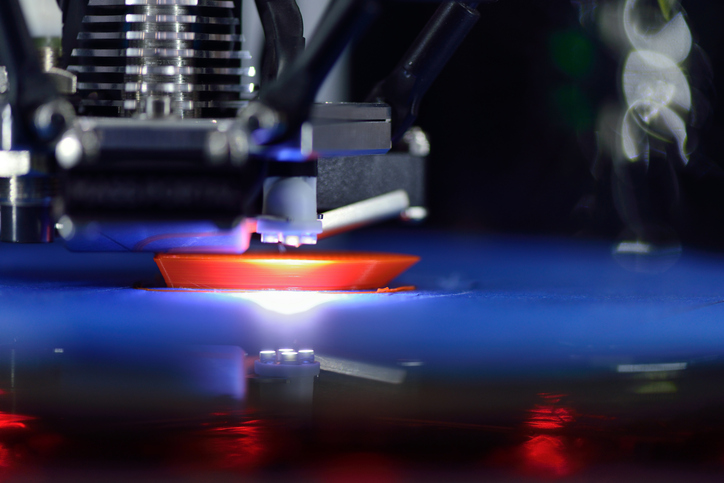

As 3D printing continues to surge in popularity and feasibility, the risk of printing software and control computers being compromised by malware has engineers turning their attention towards the security of 3D printers. A joint research team from Georgia Tech and Rutgers has developed a three-layer system to confirm the process and materials being used in the printer have not been compromised by hackers. Let’s take a closer look at how this system works, with its three layers of acoustics, tracking and detection.

- Acoustic monitoring allows the researchers to compare a printer’s setup to an acoustic recording of a correct, secure print. Any subtle variations in the way the printer’s components are set up is a signal that malware might be at play. The process is controlled with microphones and filtering software.

- Tracking movement of the printer’s components allows the research team to notice any inconsistencies. As the printer’s parts follow a precise path with every use, any variation in those paths can be considered a red flag. This is achieved by using sensors to track mechanical paths.

- Any finished, 3D-printed product has small gold nanorods in its filament. Detecting those gold nanorods is the last layer of malware detection in this system. These nanorods are detected using computer tomography and spectroscopy to accurately, consistently locate them throughout the finished product. If those nanorods are not located where they should be, it could be a sign of reduced product quality and a compromised system.

The security of 3D printers will be paramount due to the practice’s widespread applicability and the likelihood of open-sourced use. The on-demand nature of 3D printing calls for advanced security measures to make sure products are safely and efficiently produced, especially for governmental or medical needs such as infrastructure, implants, or aerospace (which is something we’ve discussed before). The next step of this 3D printing security is to make sure the three-layer system can handle larger, noisier environments that might affect its acoustics or movement tracking.

What are your thoughts on the software and hardware security of 3D printers or 3D printing in general? Let us know in the comments below.