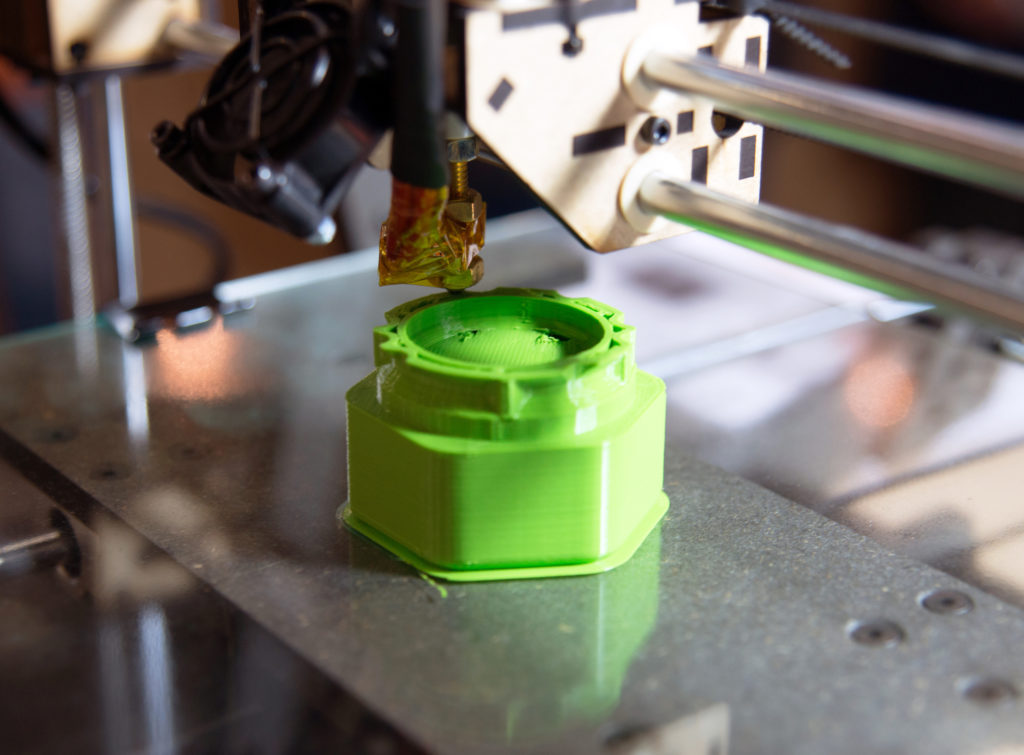

Additive manufacturing is the process of technologies that create 3D objects by adding layer upon layer of an ultra-thin material, whereas traditional manufacturing begins with a solid block or amount of material and the excess is cut away to create a finished product. A wide variety of materials can be used as additives such as plastics, metals and composite materials. It is the industrial version of 3-D printing.

Manufacturers are so interested in this technique as is uses less material therefore creating almost zero waste. Additive manufacturing also allows for designs of high complexity and they can be produced in smaller quantities without significantly varying the cost, where as traditional manufacturing costs are determined by the amount produced. Also changes to the finished product can take place and be produced in less than half the time of traditional manufacturing.

Though there are great benefits of additive manufacturing, it is currently best suited to smaller quantities of product. Traditional manufacturing carries less cost when it comes to large scale production.

GE has added Brilliant Factories that are sophisticated and primarily use additive manufacturing. They have been producing not only jet parts, but complete jet engines that are much stronger and impossible to create using traditional manufacturing. Ford is using additive manufacturing to produce engine covers that they reported the prototype to take 4 days at a cost of $3000, where traditional methods would have taken 4 months and cost $500,000.

While it may not yet be the most efficient way to produce a product in large quantities, additive manufacturing is transforming the industry and will continue to make a big impact.

Please share your comments or questions with us below and be sure to visit www.gesrepair.com or call us at 1-877-249-1701 to learn more about our services. We’re proud to offer Complete Repair and Maintenance on all types of Industrial Electronics, Servo Motors, AC and DC Motors, Hydraulics and Pneumatics. Please subscribe to our YouTube page, Like Us on Facebook! Thank you!