From airplanes to replacement machine parts, additive manufacturing, aka 3-D printing, is making an impact — and may have some longevity. It’s become so popular, in fact, that individuals are buying 3-D printers for their homes. The 3-D printers manufacturers use, however, are much larger and made for more than printing plastic models, but how is additive manufacturing used in the industry?

Jet parts

Speaking of big 3-D printers, Boeing professionals use additive manufacturing to print parts for their 787 jets. Not only are these printers “bigger than most rooms in a home” but they also cost much more — and they print titanium by melting it in a process called rapid plasma deposition (RPD).

Space-age tools

Additive manufacturing isn’t limited to jet altitudes: Astronauts used NASA 3-D technology to print a ratchet on the  International Space Station along with 19 other objects. They won’t be using the ratchet in space; however, NASA scientists are studying the differences between parts printed on the ground and those in space. With limited shipments to and from the International Space Station, additive manufacturing may change astronauts’ abilities to solve problems where they are, rather than relying on shipments from the ground.

International Space Station along with 19 other objects. They won’t be using the ratchet in space; however, NASA scientists are studying the differences between parts printed on the ground and those in space. With limited shipments to and from the International Space Station, additive manufacturing may change astronauts’ abilities to solve problems where they are, rather than relying on shipments from the ground.

Manufacturing plants

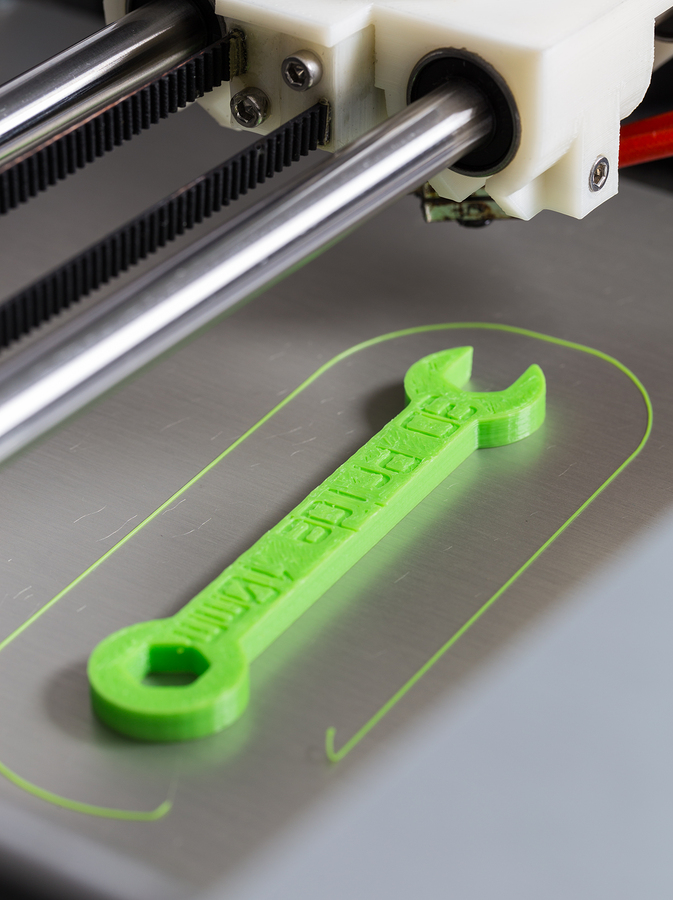

This on-demand ability also has manufacturing plant applications. With more printable materials coming to market alongside 3-D printing’s rise in popularity, some manufacturers may consider investing in this technology as part of their maintenance, repair, and operations (MRO) budgets for in-house machine part repairs and replacements.

The ability to print on an as-needed basis can save more than money: When workers can print the tools and replacement parts in near-real time, manufacturers save space on the plant floor as well. Adapting additive manufacturing technology to end-user products can also help improve space-saving measures as it reduces unnecessary stock and save manufacturers money through faster production.

Challenges and uses

One previous barrier to entry for manufacturers in particular was the cost of the printers themselves. Now that the tech is advancing and prices are falling, 3-D printing is becoming a more viable and material cost-saving option compared to subtractive manufacturing, especially because manufacturers can use the “scrap” materials for future production.

One previous barrier to entry for manufacturers in particular was the cost of the printers themselves. Now that the tech is advancing and prices are falling, 3-D printing is becoming a more viable and material cost-saving option compared to subtractive manufacturing, especially because manufacturers can use the “scrap” materials for future production.

With so much versatility — and high initial costs — 3-D manufacturing offers nearly endless options to manufacturers willing to embrace it. According to the Tulsa World article, additional applications include vehicle manufacturing, cars printed on demand, and machine repair as well as RPD printers in appliance and repair vehicles. The technology has already grown beyond small plastic gaskets and gadgets to impact manufacturers large and small and will likely continue to evolve.