Machines and systems at every production plant need regular service to achieve optimal performance. Some organization leaders consider spare parts, extra lubricants and filters, and even safety equipment as added expenses. Those who keep a ready parts and consumables supply available, however, can prevent unnecessary and costly production stoppages. Machines and parts will eventually fail; a maintenance, repair, and operations (MRO) budget can delay failure to maximize equipment life cycles and ensure optimal performance along the way.

Machines and systems at every production plant need regular service to achieve optimal performance. Some organization leaders consider spare parts, extra lubricants and filters, and even safety equipment as added expenses. Those who keep a ready parts and consumables supply available, however, can prevent unnecessary and costly production stoppages. Machines and parts will eventually fail; a maintenance, repair, and operations (MRO) budget can delay failure to maximize equipment life cycles and ensure optimal performance along the way.

Establish your MRO plan

Industry history reveals best practices

Over the past 150 years, industrial experience has guided best-practice developments for MRO. Corporate leaders adopting these practices can reduce or eliminate production downtime due to machine failures.

These company decision-makers often increase profits and elevate productivity, which correlates with improved revenue. For business leaders routinely operating within supply chains, reducing downtime can also enhance those relationships. Maintaining an adequate inventory of MRO items can be an essential part of a successful plan.

The MRO plan

Your plan should include standard elements that cover every reasonable contingency:

- An assessment informs management of existing systems, wear or failure risks and operating costs for those assets through the ends of their expected life cycles.

- Analyses indicate when and where repairs may soon be needed and facilitates routine maintenance scheduling.

- Implementing the plan includes the need to train personnel to follow scheduling, inventory tracking and other processes to ensure machines keep working.

MRO is critical to expansion

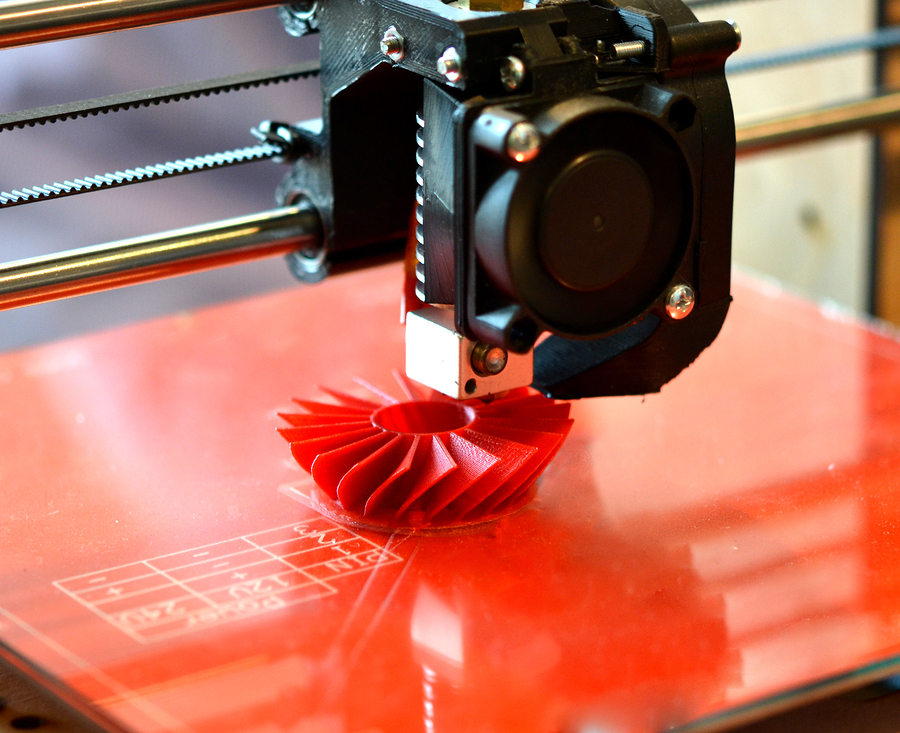

The rapidly growing 3-D printing industry offers an example of why MRO maintains corporate competitiveness in an ever-changing industrial world. Those in industries as diverse as aerospace, engineering, and health care now use 3-D printing to achieve better models, reduce research and development time length and speed market launch — so why not manufacturers? Manufacturing companies failing to maintain up-to-the-minute supply capacity, including adequate supplies of compatible materials, will also likely fail to meet the challenges new, disruptive industrial projects present.

The rapidly growing 3-D printing industry offers an example of why MRO maintains corporate competitiveness in an ever-changing industrial world. Those in industries as diverse as aerospace, engineering, and health care now use 3-D printing to achieve better models, reduce research and development time length and speed market launch — so why not manufacturers? Manufacturing companies failing to maintain up-to-the-minute supply capacity, including adequate supplies of compatible materials, will also likely fail to meet the challenges new, disruptive industrial projects present.

If you haven’t yet implemented an MRO plan in your plant, you may be heading for unnecessary slowdowns or stoppages due to machine failures. If that happens and you need experienced professionals on your side for immediate repair or replacement services, contact the experts at Global Electronic Services for your industrial electronic, AC and DC motor, servo motor, hydraulic and pneumatic needs.

If you haven’t yet implemented an MRO plan in your plant, you may be heading for unnecessary slowdowns or stoppages due to machine failures. If that happens and you need experienced professionals on your side for immediate repair or replacement services, contact the experts at Global Electronic Services for your industrial electronic, AC and DC motor, servo motor, hydraulic and pneumatic needs.