Almost every machine has some form of HMI and as technology advances it is harder to find one without some form of display component. But a common question we are asked in the service center is which type of display is best? This is a very hard question to answer, as each display type has its own pros and cons. What we can do is outline in this article what we see in for repair and some design considerations taken directly from a service center viewpoint.

Cathode Ray Tube (CRT)

CRT stands for cathode ray tube and is an older style display you might find in most manufacturing facilities. One of the main concerns with  CRT’s is something called burn-in. Burn-in is a permanent discoloration of the screen that occurs over time when the phosphor compounds which produce light to create images are overused and degrade. This is common mostly due to age, but also for the fact that machine programs often have a static display, especially if the program is a part of a process that rarely changes. Since only one part of the display CRT’s has increases power requirements when compared to other display types, as much as 200 percent, and as such require larger power supplies and generate more heat. This can lead to cabinet failures, power supply board failure, capacitor swelling and other heat related issues. We address this in the service center in a number of ways. First if the customer prefers and the application allows, we do a complete retrofit. The CRT is replaced with an appropriately sized LCD or LED display, while still utilizing the on-board video components. The display is then wired according to the customer’s design requirements and made to insure the unit will be plug and play. Apart from completely replacing the display, many repair options are available as many of the failure modes exist on the electronic display PCBs and is unrelated to the CRT itself.

CRT’s is something called burn-in. Burn-in is a permanent discoloration of the screen that occurs over time when the phosphor compounds which produce light to create images are overused and degrade. This is common mostly due to age, but also for the fact that machine programs often have a static display, especially if the program is a part of a process that rarely changes. Since only one part of the display CRT’s has increases power requirements when compared to other display types, as much as 200 percent, and as such require larger power supplies and generate more heat. This can lead to cabinet failures, power supply board failure, capacitor swelling and other heat related issues. We address this in the service center in a number of ways. First if the customer prefers and the application allows, we do a complete retrofit. The CRT is replaced with an appropriately sized LCD or LED display, while still utilizing the on-board video components. The display is then wired according to the customer’s design requirements and made to insure the unit will be plug and play. Apart from completely replacing the display, many repair options are available as many of the failure modes exist on the electronic display PCBs and is unrelated to the CRT itself.

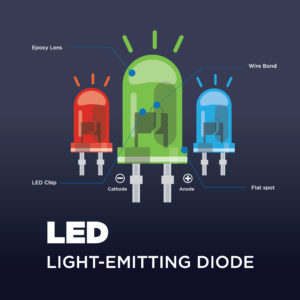

Light Emitting Diode (LED)

In the past, LED displays were simply too impractical and expensive to be used in industrial displays but just as flat panel displays caught on to consumer televisions, more and more industrial LED displays are found in manufacturing facilities across the globe. When one fails though, generally they need to be replaced. The reason for this is that one of the most common failures is a series of overheated degraded or dead pixels on the display itself. Since the pixel diodes on the surface of the screen are too small to replace, typically speaking the whole display must be replaced. Luckily advancements in engineering and manufacturing costs have made LED displays more and more affordable as time goes on.

to consumer televisions, more and more industrial LED displays are found in manufacturing facilities across the globe. When one fails though, generally they need to be replaced. The reason for this is that one of the most common failures is a series of overheated degraded or dead pixels on the display itself. Since the pixel diodes on the surface of the screen are too small to replace, typically speaking the whole display must be replaced. Luckily advancements in engineering and manufacturing costs have made LED displays more and more affordable as time goes on.

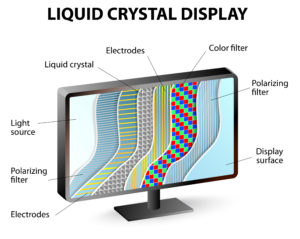

Liquid Crystal Display (LCD)

LCDs or liquid crystal displays are now the dominating display type on the market. They are versatile, offer a good picture, are becoming  more affordable every year and have become a standard on most modern machine HMIs. Fortunately, while they do have their downsides and failures, most are repairable. LCD’s utilize a small power supply conversion board called an inverter. The inverter is necessary to provide power to the LCD. The trouble is, since space is a design concern, manufacturers have to make this device within a very small profile. This causes problems because we find that some of the passive components (such as capacitors, resistors and diodes) are undersized and susceptible to failure. We address this by either replacing the LCD inverter entirely or if this is not possible, replacing the bad components with ones with higher tolerances for electrical noise and heat.

more affordable every year and have become a standard on most modern machine HMIs. Fortunately, while they do have their downsides and failures, most are repairable. LCD’s utilize a small power supply conversion board called an inverter. The inverter is necessary to provide power to the LCD. The trouble is, since space is a design concern, manufacturers have to make this device within a very small profile. This causes problems because we find that some of the passive components (such as capacitors, resistors and diodes) are undersized and susceptible to failure. We address this by either replacing the LCD inverter entirely or if this is not possible, replacing the bad components with ones with higher tolerances for electrical noise and heat.

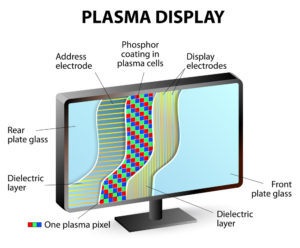

Plasma

Plasma displays are utilized for their rich color and sharp contrast. They also perform very well in dark environments where brightness is a  concern. Despite these advantages plasma displays have suffered to gain popularity in industrial applications because of their cost in manufacturing and due to the fact that picture quality is not a chief concern especially since the display is being used in a non-entertainment capacity. In addition, when they fail there is little you can do but replace the display inside the device. In the service center we are asked often to engineer a retrofit from plasma to another display type to reduce cost to the customer and in cases where a LED or LCD display is preferred. Like CRTs, plasma displays are much more susceptible to burn-in when compared to other flat panel display types.

concern. Despite these advantages plasma displays have suffered to gain popularity in industrial applications because of their cost in manufacturing and due to the fact that picture quality is not a chief concern especially since the display is being used in a non-entertainment capacity. In addition, when they fail there is little you can do but replace the display inside the device. In the service center we are asked often to engineer a retrofit from plasma to another display type to reduce cost to the customer and in cases where a LED or LCD display is preferred. Like CRTs, plasma displays are much more susceptible to burn-in when compared to other flat panel display types.

There you have it, the pros and cons of different display types and some of their common failures. Remember, if you suffer a failure of any display type, we are here to help. Be sure to visit us online at www.gesrepair.com or call us at 1-877-249-1701 to learn more about our services. We’re proud to offer Surplus, Complete Repair and Maintenance on all types of Industrial Electronics, Servo Motors, AC and DC Motors, Hydraulics and Pneumatics. Please subscribe to our YouTube page and Like Us on Facebook! Thank you!

Do you retrofit CRT displays with an LCD display when the CRT is receiving an EGA video signal?

The video boards we use as part of our conversion are auto-ranging. They can cover CGA, VGA and EGA. The more important engineering question would be what kind of video cable you are using, as that can sometimes effect how we do the conversion.

Great! Love that answer! We have lots of old monitors that may need retrofitting in the future.