When I first began my career in electronics one of my fondest memories was my first introduction to “the magic smoke test”. The test is essentially when you power on any electrical device for the first time it must power on without releasing any of its “Magic Smoke”. The humor of this is of course the suggestion that if the device “holds in its smoke” (IE doesn’t pop, smoke or burn), then clearly it works and that somehow this “smoke” is the key to its function.

This whole concept is a logical absurdity. There is no “Magic Smoke” that flows through electronics to make them work. The real truth is that when a piece of electronics burns there is one of two common causes. Overload or Short Circuit, (there are others but these are the most common we see in the service center). These terms are somewhat ubiquitous and when it comes to failure analysis they are often confused and used interchangeably. But the two conditions are actually two separate events, each with their own specific cause.

Overload

Electricity or current is the flow of free electrons through a conductor such as copper or aluminum wire. When this current flows through the conductor a specific amount of heat is generated. The higher the current the more heat is generated. Any conductor (for example a piece of wire or a trace on a circuit board) has only a certain amount heat energy it can withstand. Usually this is based on size and type of material. One cause of a rise on this heat energy in a circuit is an “Overload” condition. This is when too much current is drawn through an electrical circuit beyond its capabilities. A good example of what could cause this would be too many devices plugged into the same circuit. This excessive current draw causes insulating materials to break down and ultimately resulting in a fire. There are many causes of this ranging from mechanical failures to misapplication and everything in between.

Short Circuit

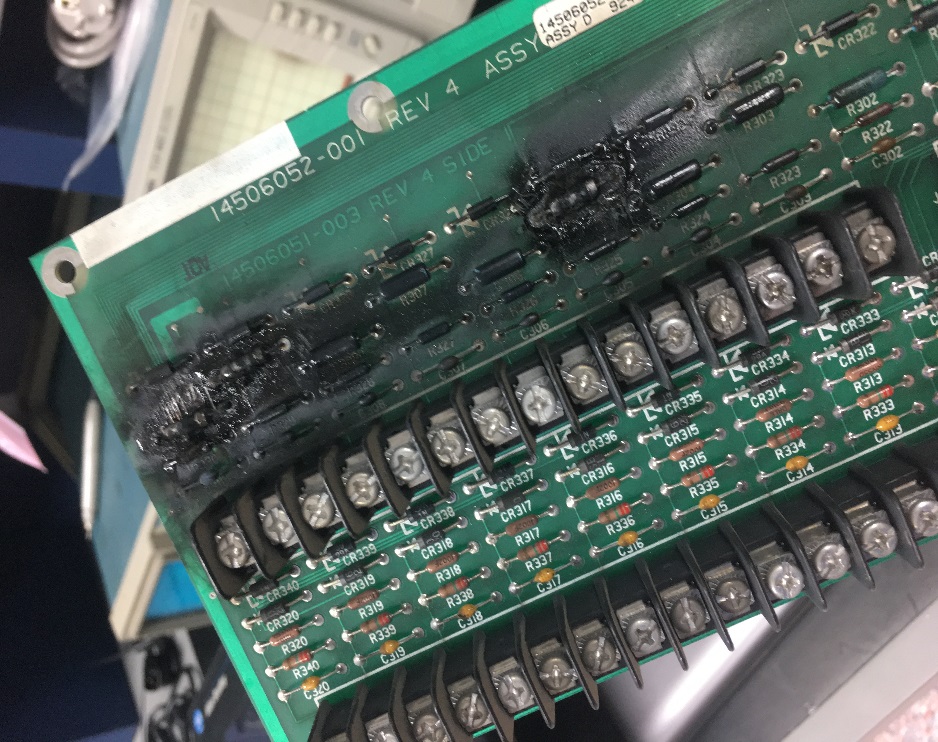

OF course while conductors carry electric current between component to component, insulating materials keep the current on its designated path. Most often wires are shielded with rubber or plastic while printed circuit board traces are surrounded by a substrate made out of glass-material. In fact this glassy solder mask is why many circuit boards are green in color. If two conductive materials were to make contact without an insulator between them a “path of least resistance” is created which is referred to as a short. Without the insulating material, such as the above mentioned rubber, glass and plastic, the amount of current draw rises exponentially. This high current results in immediate overheat and damage to the circuits as whatever materials are present are burned up by the excess heat energy.

These two conditions can be caused by many things. In overloads we see failures such as mechanical jams of driven equipment, relay or distribution failure, and even operator error. The shorts we see can be caused by anything from contamination, like a water spill acting as a conductor between two circuits, to employee mishap, such as a loose screw falling across two uninsulated conductors or finally improper wiring and hookup. Whatever the cause, these two failures are common and it is important when performing your failure analysis to know the difference.

Please share your comments or questions with us below and be sure to visit www.gesrepair.com or call us at 1-877-249-1701 to learn more about our repair services. We’re proud to offer Complete Repair and Maintenance on all types of Industrial Electronics, Servo Motors, AC and DC Motors, Hydraulics and Pneumatics. Please subscribe to our YouTube page, Like Us on Facebook! Thank you!

Looks like maybe the Zeners shorted and fried the resisters out! It all depends on what the Zeners’ job was. I’m not sure, BUT as far as my Electronics Knowledge goes, I’d call for replacement rather than repair. It looks like Board (Trace) damage and if signals other than power through those traces – Then replace. I guess that ONLY question I could ask, What happened (User) to cause this…..OR was it an inherit weakness that took years to show. I’ve seen despicable designs, oh like, putting an Electrolytic Capacitor RIGHT next to a Ceramic Block Resister! RCA Tube TVs just before the Flatscreen revolution! :-O 😀

🙂 Lots of trace damage repair for sure 🙂