If machines on your assembly line are still functional after long lives of heavy use, it’s time to pat yourself on the back for maintenance well-done. Most machines have expected life spans, after which they’re likely to break down and need to be replaced. But by following maintenance best practices, most machines can provide years of value beyond their predicted life spans. In fact, performing preventive maintenance on equipment could deliver a 545% return on investment — no, that’s not a typo — most of which comes from extending machine life.

Some old machines are still doing their jobs

Don’t believe it? Here are some examples of exemplary machines that, with the help of good upkeep, have stood the test of time and are still running today.

A General Electric refrigerator purchased for $300 around 1930 is still keeping groceries cool today for a couple in Montgomery, New York. That’s over 85 years of refrigeration! This is especially impressive when compared to today’s refrigerators, which have average life expectancies of 14 years. Refrigerators are fairly complex machines, and they could require maintenance as simple as filter changes or as challenging and necessary as motor replacements. Luckily, every single piece of a refrigerator is replaceable, so with the right attention, another fridge could beat that GE fridge’s record generations down the line.

Source: Caters News

Keeping your food in an 85-year-old refrigerator is one thing, but would you trust your safety to a car nearly 50 years older? The oldest running car runs on a steam engine and is over 130 years old. The average car on the road today is less than 10 years old — so even the best maintenance probably wouldn’t make your Chevy last until 2146! Of course, while the steam engine might be long-lived, it produces a level of pollution our modern society no longer accepts. But with excellent care, it’s totally reasonable to expect many modern cars to live to see 200,000 miles, which could come out to 20 years for some Americans.

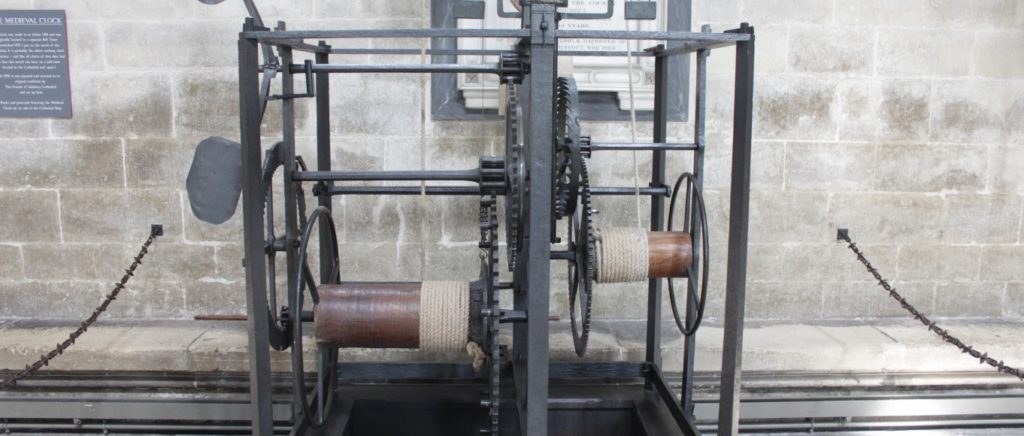

Nearly four times as old as that car, though, is the 498-year-old clock at Salisbury Cathedral in Wiltshire, U.K. This clock is the oldest working clock and has only been restored once, in 1956. Clocks have a well-established spot in our history as long-lived machines, whether they be tourist attractions at historical landmarks or simply the grandfather clock that’s been passed down among generations, but this clock puts even those timepieces to shame.

Source: Salisbury Cathedral

Compared to the looms artisans use to this day to weave fabrics at Luigi Bevilacqua, a Venetian fabric manufacturer, the car and fridge seem positively youthful. Weavers still use these looms created in the 18th century today to create beautiful velvets, damasks, and brocades that hold Italian history in their fibers. Each weaver spends a year training to use the 25 hand-operated looms to create her or his own fabrics.

These old machines are striking not just because of their ages but also because every person who has used and maintained them over the course of their lifetimes has kept them well-maintained and in constant use. With this kind of attention to care and upkeep every day, your equipment, too, could have a longer life expectancy than any manual could predict.