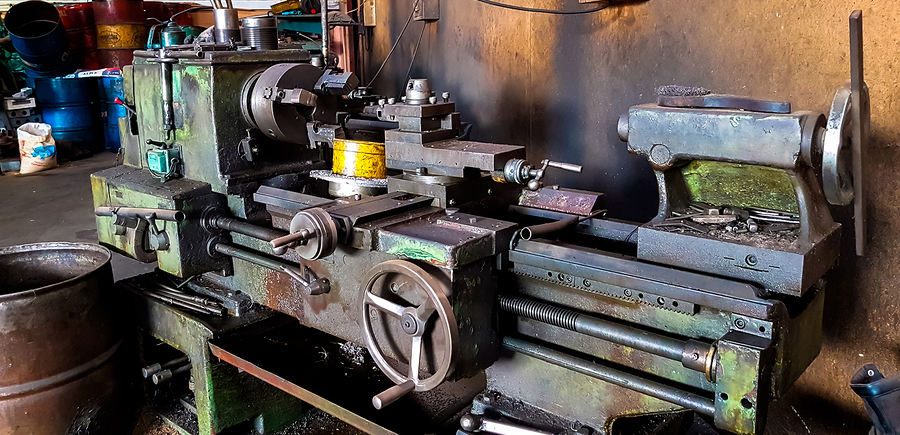

Let’s take a walk along your manufacturing plant floor. Are some of your machines silent because they stopped working? Are you unable to find replacement parts because they’re so old? Do workers stand around other machines while mechanics fix them for the umpteenth time this week or month? And what about your remaining machines: Are their working lives coming to an end soon?

If you answered “yes” to the majority of these questions, it may be time you upgrade. Yes, that involuntarily groan means you know you need to get started — but where can you begin? Here are a few things to consider:

Benefits

Actually, many benefits. First, you won’t continue to lose business due to your machines constantly being down. The revenue you receive with a smooth-running plant will likely equal or outmatch the investment you make to upgrade. Second, you don’t have to upgrade everything all at once or cause too much downtime, meaning product creation continues and employees remain productive. To achieve this, you need to determine which machines are most important for immediate upgrade. Third, upgrading to top-of-the-line equipment and providing extensive training to employees helps increase their happiness and safety at the plant. That, in turn, increases their productivity.

Setbacks

Not everything will go perfectly for every plant manager every time. For example, the machinery you want may fit neither in your plant space nor in your operating budget. Even if it does fit in the space, your board may deny the acquisition because members feel it’s not worth the investment. If you do get a chance to upgrade the machinery, it may be automated a great deal, meaning you may have to deal with an employee skills gap. Then there’s the downtime upgrades require. Even if it’s just one machine, the potential for it not working properly at the start can lead to a huge production delay. But these are minor compared to the biggest setback: If you don’t consider machinery upgrades, your production line could completely stop.

Not everything will go perfectly for every plant manager every time. For example, the machinery you want may fit neither in your plant space nor in your operating budget. Even if it does fit in the space, your board may deny the acquisition because members feel it’s not worth the investment. If you do get a chance to upgrade the machinery, it may be automated a great deal, meaning you may have to deal with an employee skills gap. Then there’s the downtime upgrades require. Even if it’s just one machine, the potential for it not working properly at the start can lead to a huge production delay. But these are minor compared to the biggest setback: If you don’t consider machinery upgrades, your production line could completely stop.

Plans

You can prevent many of the setbacks mentioned above through proper planning — but not when your plant is about to stop production. When you start seeing more machinery failures, it’s time to implement a replacement plan. This includes measuring the plant floor, examining your budget, and reviewing potential downtime for new equipment installation. Once you’ve purchased your equipment, create a schedule to phase in the machinery over time.

Training

The good thing about downtime during upgrades is your employees have the chance to train on using the new equipment. Training is immensely important for two reasons. One, it allows employees to start working on the machinery on startup and without further delay. Two, it provides comprehensive safety coaching so stoppages don’t occur due to accidental injuries — or vice versa. Training and cross-training employees on new equipment is of utmost importance when creating an upgrade plan.

Sure, some manufacturing plant leaders could experience setbacks when upgrading plant machinery, but, with your comprehensive plan and employee training in place, you can mitigate such issues in your workplace. Overall, upgrade benefits tend to far outweigh setbacks when it comes to your productivity and profit.