Motors are big investments and pains for company accountants to work around when they need replacement. Though motors and their lifespans have improved over the years, they’re still susceptible to failure. Maintaining your motors can save you a pretty penny in the long run.

In fact, 51% of motor failures are related to improper bearing use. Luckily, companies are developing methods to monitor bearing status with internal sensors or ultrasonic measures. But until these products become mainstream, you can use several troubleshooting techniques to avoid bearing problems.

According to the ABB eBook, re-greasable bearings require regular maintenance, but it’s important not to over-grease or re-grease bearings sealed for life. Inefficient or excessive greasing can overheat bearings and lead to motor failure. Use a probe to test temperatures if you’re worried about overheating.

According to the ABB eBook, re-greasable bearings require regular maintenance, but it’s important not to over-grease or re-grease bearings sealed for life. Inefficient or excessive greasing can overheat bearings and lead to motor failure. Use a probe to test temperatures if you’re worried about overheating.

Proper grease application can help avoid motor failure. To ensure an appropriate amount, refer to the motor manufacturer’s operations manual.

Prior to application, make sure the relief valves are clear of dirt, hardened grease, or other debris. Keep valves open during the re-greasing process so excess grease can escape from the bearing housing. During the re-greasing process, it’s important you apply grease into the bearings slowly, pumping every few seconds. Pumping too fast can build pressure, which can damage seals.

It’s equally important you use the right grease type or grade. Good-quality ball bearing grease is made with lithium complex soap and with mineral or PAO-oil. As a standard procedure, it’s always best to check the lubricants section of the motor operations manual before choosing and applying grease. Don’t — under any circumstances — mix different types of grease. Even if you follow proper greasing procedures, using incompatible lubricants can damage bearings.

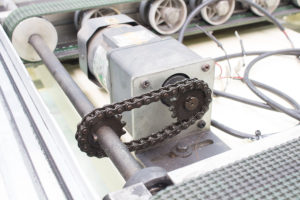

![]() In addition to proper lubrication, you must ensure your motor and load are always correctly aligned. Temperature changes can affect motor and load connection alignment. Check and correct alignment after the motor and machine have reached their maximum temperatures. In addition to excessive temperature checks, you should check your motor alignment about every 2,000 hours. Shaft overloads and excessive vibration can also cause bearings to malfunction and lead to motor failure.

In addition to proper lubrication, you must ensure your motor and load are always correctly aligned. Temperature changes can affect motor and load connection alignment. Check and correct alignment after the motor and machine have reached their maximum temperatures. In addition to excessive temperature checks, you should check your motor alignment about every 2,000 hours. Shaft overloads and excessive vibration can also cause bearings to malfunction and lead to motor failure.

Paying close attention to your machines and troubleshooting parts when they show signs of wear can help you better protect against failure — and save you a lot of money in the long run.