When it comes to the Industrial Internet of Things (IIoT), those who aren’t yet working with connected devices daily in their manufacturing plants might feel like outsiders. Traditional manufacturing still plays an important role, but, by 2030, IIoT processes could enhance long-term career growth in the sector, grow the global economy by trillions, and bring more operations onshore. With industry leaders moving their processes into this new era, where can manufacturers interested in moving to the IIoT without previous technical knowledge begin?

Start simple

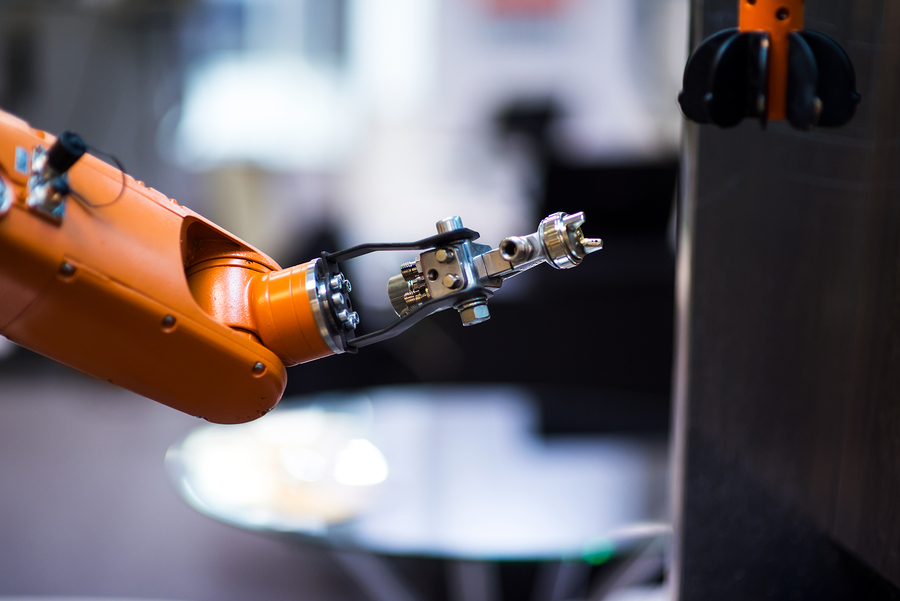

Intelligent IIoT systems using robotic arms are effectively simple: They’re made up of the robot arm and a communications network. The communications network includes a controller and an effector. The controller and effector include the programmable logic controller (PLC) itself, drives and transport systems, and sensors. While the PLC manages the network, it also commands actions to the drives. These engines power the transport systems and allow the robot to connect to the network and maneuver in its work environment. The sensors monitor the process as well as environmental changes and provide information on the system’s status.

Intelligent IIoT systems using robotic arms are effectively simple: They’re made up of the robot arm and a communications network. The communications network includes a controller and an effector. The controller and effector include the programmable logic controller (PLC) itself, drives and transport systems, and sensors. While the PLC manages the network, it also commands actions to the drives. These engines power the transport systems and allow the robot to connect to the network and maneuver in its work environment. The sensors monitor the process as well as environmental changes and provide information on the system’s status.

These intelligent systems are easily reprogrammable and allow manufacturing professionals to focus on higher-level tasks as they don’t require human interaction.

Intelligent manufacturing

Intelligent devices like these robot arms, intelligent people using wearable devices working alongside them, and intelligent processes encompassing robots and manufacturing professionals are ushering Industry 4.0 into our IIoT-connected era.

Intelligent devices like these robot arms, intelligent people using wearable devices working alongside them, and intelligent processes encompassing robots and manufacturing professionals are ushering Industry 4.0 into our IIoT-connected era.

In addition to smarter plant floor activities, manufacturers embracing the IIoT can also reap predictive maintenance benefits. These include, according to the Accenture report, up to 12% savings in regularly scheduled repairs, reducing maintenance costs as a whole up to 30%, and up to 70% less machine breakdowns.

Those who adapt these intelligent manufacturing technologies can decrease total cost of ownership, increase return on investment, ensure quality and compliance, increase visibility, and enhance system efficiency. Those who remain fully traditional in their manufacturing technologies may become less competitive compared to IIoT-enabled counterparts, missing these opportunities.

Manufacturers looking for a place to begin their IIoT journeys can start simply by adding a single robotic arm. A full plant redesign and additive manufacturing implementation are not necessary to begin to leverage the opportunities the IIoT can bring to savvy industry leaders. And, as they grow in their use of IIoT-connected devices and move toward fully intelligent manufacturing plants, they can continue to add to their operations piece by piece. This saves them time and money as opposed to shutting their plants down and replacing still-functioning machines with intelligent devices.