Manufacturers have long since proven their ability to create parts with complex geometries using 3-D printing. One aspect of additive manufacturing even industry insiders tend to underappreciate, however, is using it to lower the cost of producing parts and products. Here’s what all manufacturers need to know about the cost advantages additive manufacturing can offer.

Direct savings through additive manufacturing

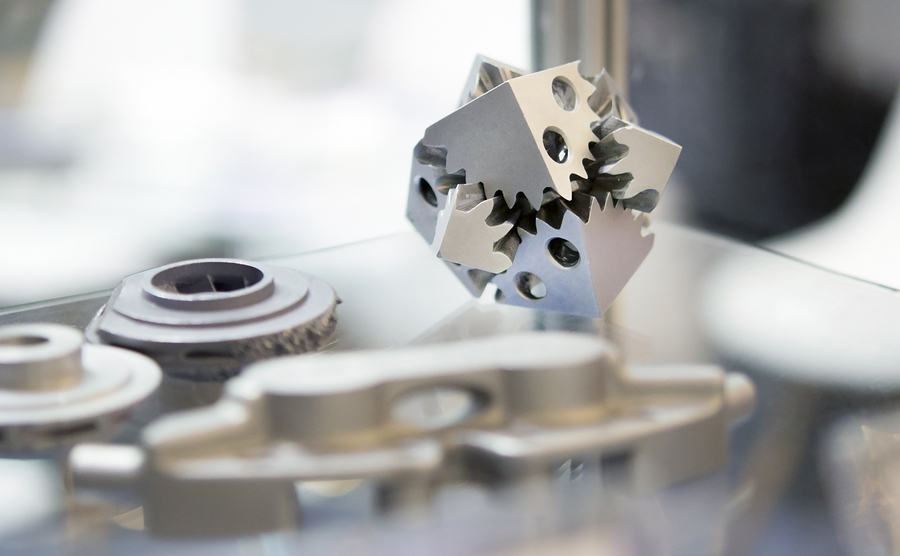

Implementing 3-D printing technology can save manufacturers money in several different ways. 3-D printing wastes less material than other forms of manufacturing. At the same time, it facilitates lighter and stronger designs based on lattices, honeycombs, and other arrangements. As a result, most parts cost less to make with 3-D printers than with more traditional forms of manufacturing. In addition, because manufacturers can create 3-D-printed parts as they are intended to be used, integrating additive manufacturing can also help them cut down on post-production processing, finishing, and assembly costs. Also, because additive manufacturing allows for the creation of a virtually infinite range of objects using a single machine, it brings the cost of part and product customization down still further. Of course, 3-D printers can’t achieve optimal savings on their own; instead, manufacturers must optimize material usage and allow for minimal processing during the design process.

Other technologies can work in tandem with additive manufacturing

Though 3-D printing has come a long way, other technologies are also gradually helping to increase associated cost savings. 3-D printing automation is likely the most important development on the horizon from a cost perspective as it will allow printers to run around the clock and produce parts far more efficiently. But that doesn’t mean this increased uptime and the associated income it could provide manufacturers are very far from reach. In fact, developers are already introducing cells that house multiple printers with robotics that can remove finished parts from build platforms. Similarly, developers are also creating automatic systems to monitor the quality of the parts these 3-D printers are producing. By reducing the need for rework through automated quality control, manufacturers can continue enhancing their bottom lines.

Technological advances are also increasing the range of materials manufacturers can use in 3-D printing. Polymer printing has already reached a fairly advanced stage. Additive manufacturing using metals like aluminum and titanium, however, is an area ripe for continued research and development. Though metal 3-D printing is quite possible and indeed common in advanced manufacturing operations, the high-end printers needed to create metal parts have historically made such printing cost-prohibitive. Now, those costs are beginning to come down, making metal additive manufacturing more accessible to manufacturers in small- and medium-sized businesses.

How can additive manufacturing create peripheral savings?

In addition to cutting actual production costs, additive manufacturing has the capacity to produce significant savings in design and logistical expenses. The ability to quickly create one-off designs using 3-D printers brings down prototyping costs and makes it possible for designers to create several prototype iterations in shorter periods. In print-on-demand models, additive manufacturing reduces the need for warehouse space as well as long-term part and finished product storage. Finally, additive manufacturing can greatly shorten the supply chain and reduce transportation expenses for parts: Manufacturers can now transmit digital files to distributed facilities and print parts where their customers need them as opposed to manufacturing in a single central location and then delivering the parts.

With so many advantages and great strides in technology every year, it’s likely additive manufacturing will continue playing a key role in bringing down the cost of producing goods. If you want to take advantage of these cutting-edge capabilities for your manufacturing business and save money in the process, additive manufacturing is a technology you may consider investing in.