It’s 7:30 on a crisp morning in November down in sunny Georgia. Our Lead Engineer, one of our Servo Motor Technicians and myself are on a conference call with one of our biggest automotive customers. In attendance on their side of the phone is the Plant Manager, Vice President of Production and one very unhappy Maintenance Supervisor. The hot topic on hand? Preventative maintenance of Servo Motors.

What brought on the call? It is a story we have heard before, a servo motor on one of their critical CNC mills went down on second shift, and the company began losing tens of thousands of dollars per day. As the maintenance crew scrambled to find the source of the problem, (as well as finding out that a new motor had a 20 week lead time with the OEM), the company was facing a hefty fine from their automaker customer for every day they were late with their parts delivery. Needless to say, things had to happen fast.

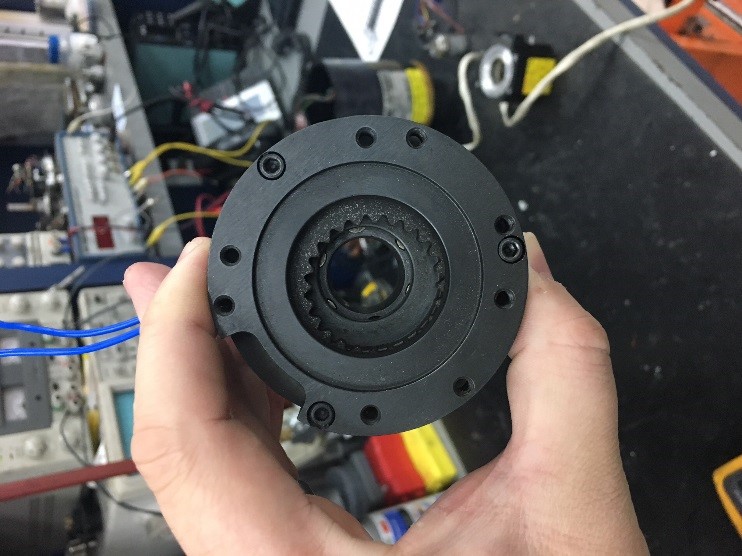

The servo motor was dashed same day air into our service center, the failure was not catastrophic and the repair was able to be turned around quickly. The cause of failure? The motor had carbon dust contaminating the encoder resulting in loss of feedback to the drive. During inspection, the shaft, endbell and connector seals were all in very good condition. So where did the dust come from? The answer: the motor had a 24 volt brake, which over time, experienced wear; and from that wear came the carbon dust that was able to creep in past the rear bearing seals and into the encoder housing. The encoder had to be replaced and was one that we stock in house.

Once the repair was finished, installed on the machine and the dust had settled, (pun intended), everyone could now breathe a deep sigh of relief. But was this a preventable failure? Certainly it was the million dollar question that management wanted an answer to on the call we were on (and from the way the conversation was going they were holding the maintenance supervisor highly responsible for said answer).

At first glance, this is a nightmare situation for any maintenance supervisor. Normally, when properly maintained, lubricated and otherwise serviced by a well-trained maintenance staff, electric motors will generally last a very, very long time. But maintenance on a servo motor is extremely difficult, if not impossible for a regular maintenance technician to be able to handle without highly specialized equipment and training. This has led many to believe that PMs (preventative maintenance) just simply cannot be performed on servo motors. When given the information that the servo motor essentially “failed on its own”, meaning no outside environmental or miss-application of the motor was the cause, the easy conclusion to jump to is that nothing could have been done to prevent this kind of failure.

So let’s talk about what led to the failure in the first place.

Any mechanical device where two pieces of material regularly make contact will eventually experience some wear and tear. A servo motor’s brake is no exception, no matter how good the design. The by-product of this friction is carbon dust, not unlike the dust that a car’s brakes can produce. But unlike a car’s brake where the dust is regularly flung off into the open air, a servo motor’s brake is enclosed in the motor housing and has nowhere to go. Normally this is not a problem as the OEM has added seals, both where the brake meets the stator, and where the brake meets the back-bearing journal to prevent the brake dust from entering into other parts of the motor. But with factors such as temperature, heat and time these internal seals are prone to deteriorate.

What servo motor failures can happen as a result in brake dust intrusion? The common ones we see are the following:

- a rear brake seal fails between brake and rear bearing, leading to dust working into the back bearing, drying up lubrication and leading to failure

- the rear brake seal fails leading to dust contaminating the feedback device, whether it be an encoder or resolver

- the front brake seal fails leading to dust collecting in the airgap between the rotor and stator resulting in a failure, especially in the case of permanent magnet motors

- dust collecting in any on-board electronics or sensors resulting in their failure

- general overheating conditions brought on by any of the above

So can premature brake-caused failure be prevented? The short answer is yes, but there are some things to look out for on a servo motor with a brake, that may escape maintenance personnel that are more experienced with regular AC induction or even DC motors. Some of these symptoms are:

- Is the motor making any unexpected sound when the motor brake is engaged? The normal sound should be a sharp click, rather than any sort of loud shriek, growl or otherwise odd noise. Compare this sound to other braking motors you may have in the facility if you have any suspicions of a failure.

- If the feedback device has a shroud that will open without affecting the alignment of the encoder, be careful, check with your motor’s manual to be sure, perform a visual inspection to see if there is any carbon dust present. This can be a sure sign of an eventual failure.

- Are the bearings making a grinding noise similar to what you would expect an under-lubricated motor bearing to make? This can be a sign that brake dust has made its way into the bearing journal.

If you run into any of these symptoms, it is usually something that can be serviced quickly and can prevent a lot of damage to the motor or even the equipment it is driving. Having a braking servo motor regularly serviced by a reliable repair center can be the key to preventing unexpected downtime as they are more prone to failure than other servos. Another consideration is that servo motors are generally very specialized, expensive and often not in stock at the manufacturer. Having them maintained regularly by a service center can be the difference between one day of maintenance, weeks or even months of downtime.

Like we say in the shop. If it brakes, it breaks.

Please share your comments or questions with us below and be sure to visit www.gesrepair.com or call us at 1-877-249-1701 to learn more about our repair services. We repair Industrial Electronics, Servo Motors, AC and DC Motors, Hydraulics and Pneumatics.